Top 10 Battery Liquid Cooling System Companies in USA

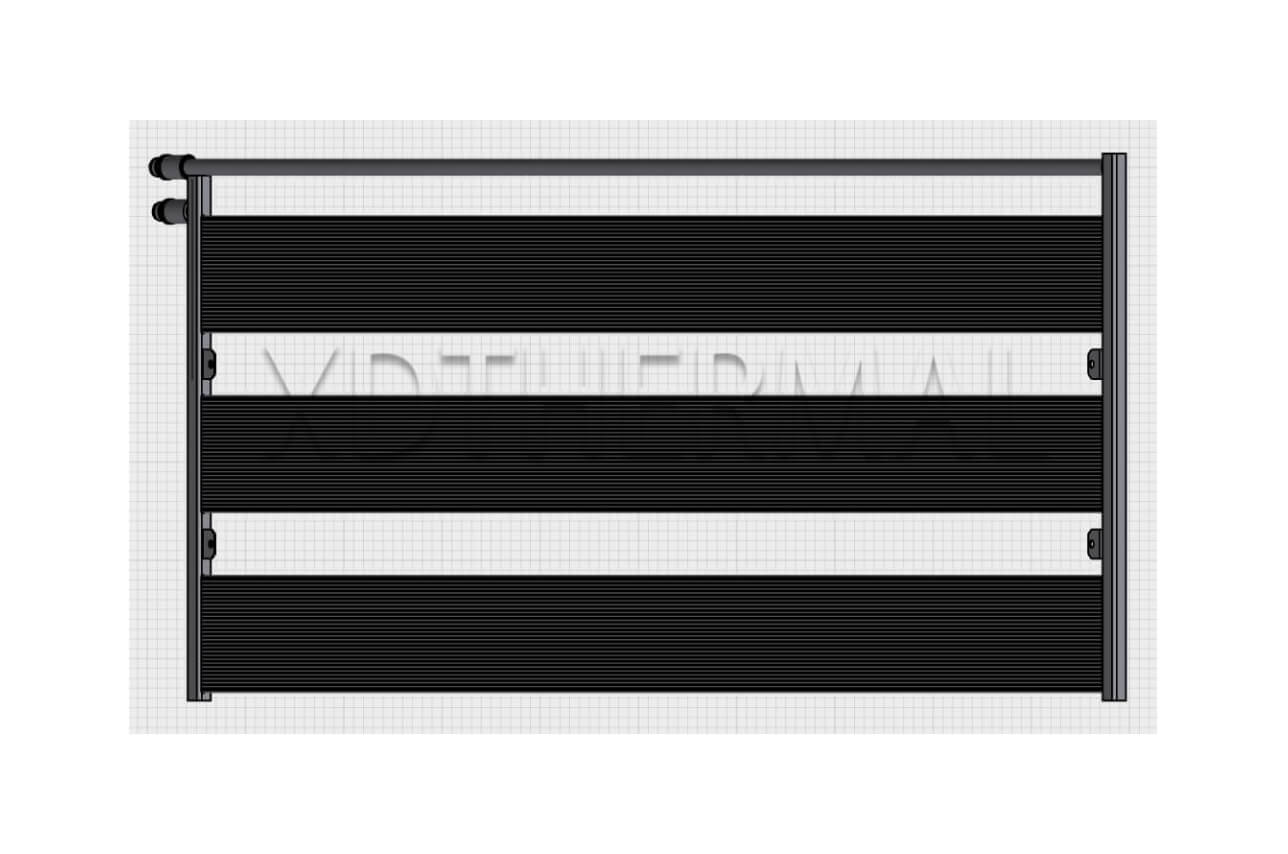

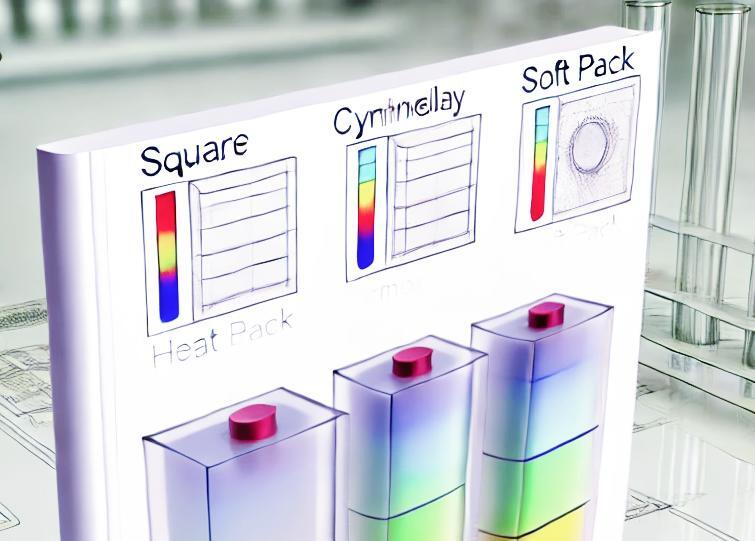

Top 10 Battery Liquid Cooling System Companies in USA With the rapid growth of the electric vehicle (EV) and renewable energy storage markets, the importance of battery liquid cooling systems is growing. These systems not only effectively manage battery temperature and extend battery life, but also improve charging speed and overall performance. The U.S., being at the forefront of technological innovation, has seen a number of companies emerge in this field. Through continuous technological innovation, they provide advanced battery liquid cooling solutions that help electric vehicles and energy storage systems run efficiently. In this article, I will introduce you to the top 10 battery liquid cooling system companies in the US. Table of Contents XD THERMAL TECHNOLOGY CO.,LTD Location: Suzhou, China Company type: Manufacturer, R&D, Design, Production The number of employees: 500+ Main products: Prismatic cooling plate, Cylindrical cooling pipe, Battery enclosure, Design& simulation Main application: Electrical vehicles, Energy storage systems, Solar systems, Heavy duties, eVTOL, Marines Website: https://www.xdthermal.com Although XD Thermal is not based in the United States, we have earned recognition for our commitment to innovation and quality in the field of battery liquid cooling systems, particularly for the manufacture of liquid cooling panels. We specialise in cutting-edge liquid cooling solutions, providing comprehensive thermal management solutions for power batteries. We are honoured to enter the US market and become their benchmark, and we acknowledge the potential of our competitors, whose tireless efforts may put them on the list. VERTIV Location: United States Company type: Design, Production, Manufacturing, R&D The number of employees: 27,000 Main products: Uninterruptible power supplies, Rack coolin, Battery storage systems, Switcharge and switchboards, Bus bars、DC power systems Website: https://www.vertiv.com/en-us/ This company is a publicly traded company with 22 manufacturing and assembly locations, 19 customer experience centres, 750,000+ customer site connections, 2,740 patents issued globally, 240+…