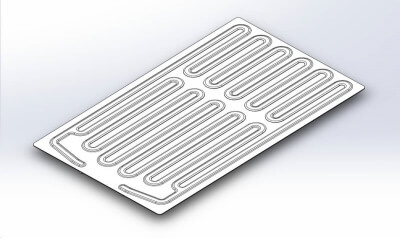

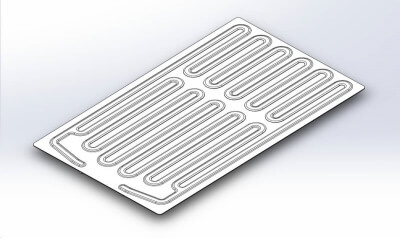

For Battery Cooling Plates

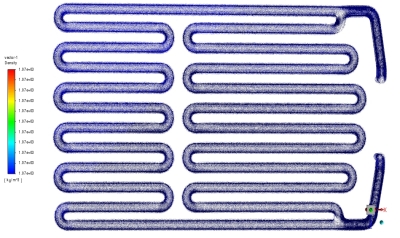

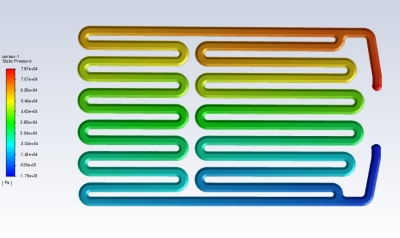

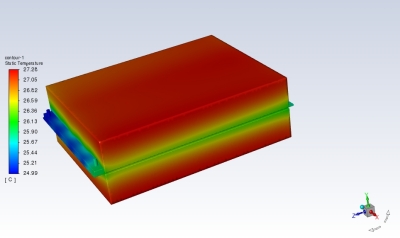

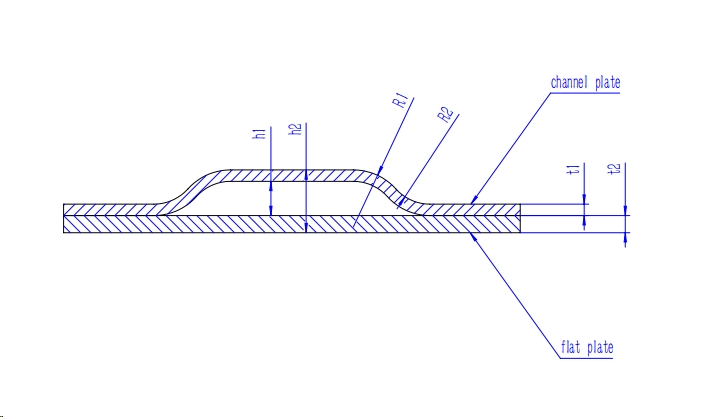

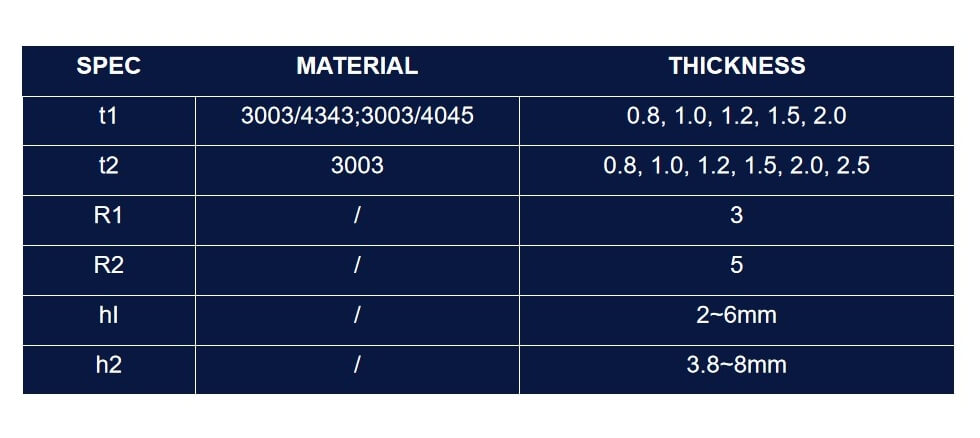

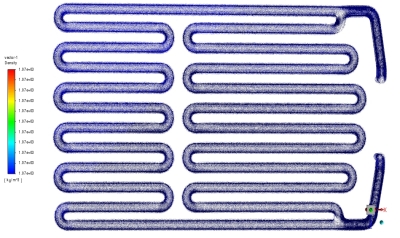

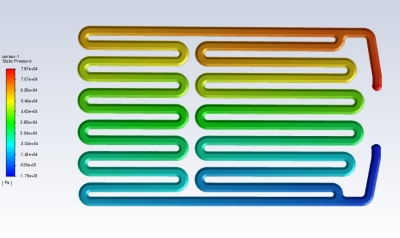

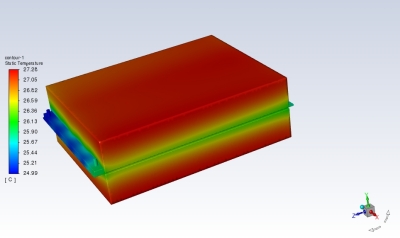

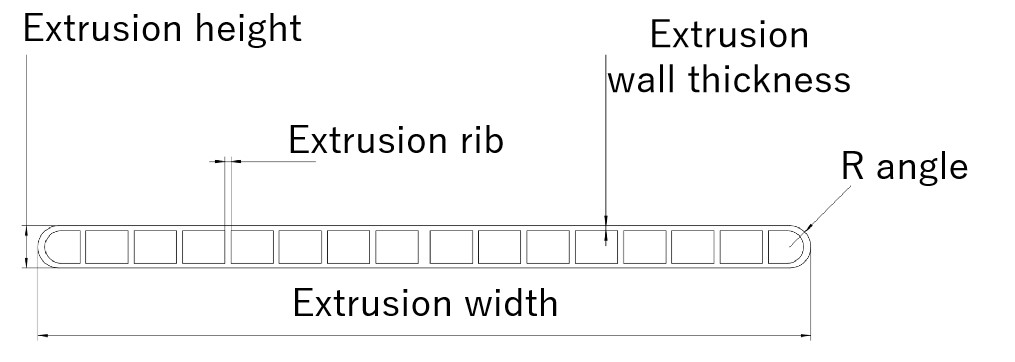

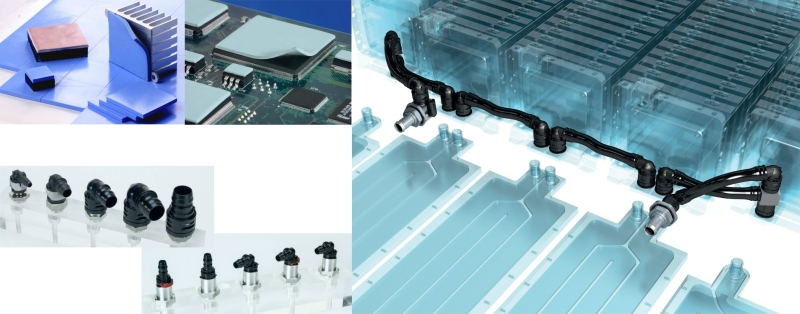

Through strategic material choices and CAD optimizations, XD THERMAL achieves a substantial 15.6% reduction in procurement costs per project, ensuring our cooling plates are not just lighter and stronger, but also align with 98.7% of industry-standard battery types. This meticulous engineering is crucial for advanced thermal management in EVs, ESS(energy storage system), and solar systems applications.

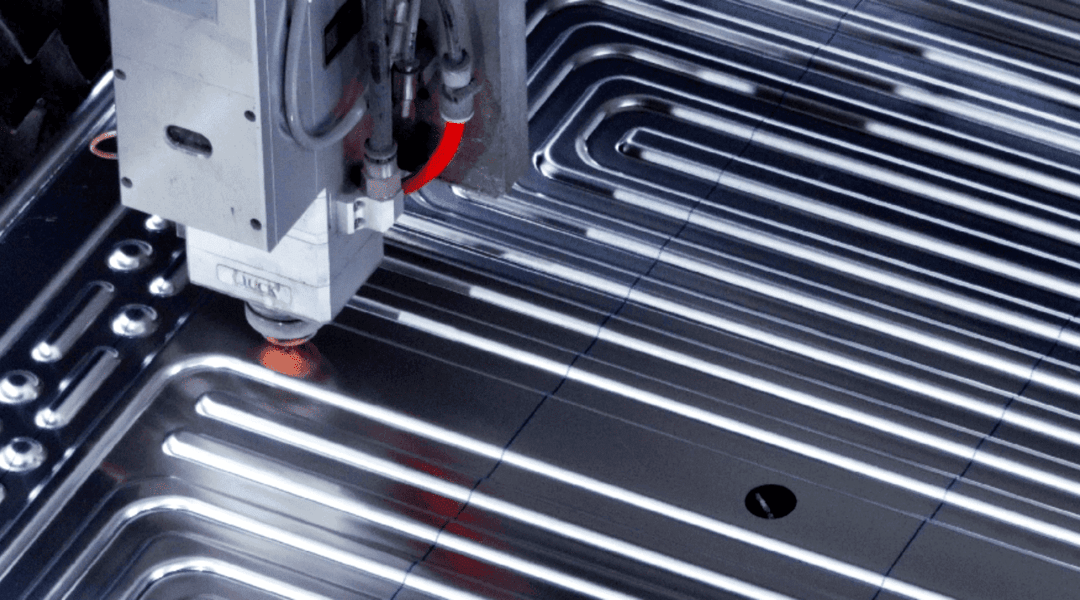

Additionally, our innovative designs promote greater manufacturing flexibility, leading to significant reductions in energy and material consumption. This advancement in manufacturing technology underscores our commitment to sustainability and our mission to deliver cutting-edge, efficient cooling solutions, making them both environmentally friendly and cost-effective for a wide range of applications.

You can save up to 15.6% on your costs

Initial drawing optimisation expected within 2 days