Friction stir welding

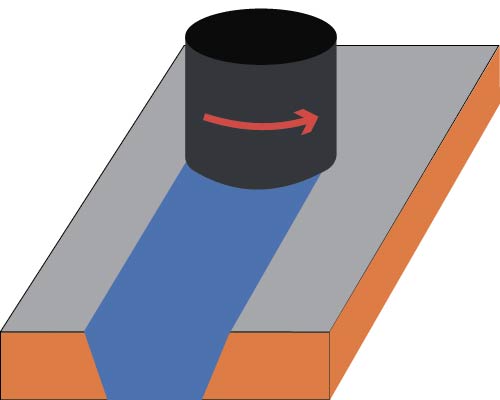

Friction stir welding definition Friction stir welding refers to the process of locally melting the material to be welded using the heat generated by the high-speed rotation of a welding tool in friction. As the welding tool moves forward along the welding interface, the plasticized material flows from the front to the rear of the tool under the action of the rotational friction force and forms a dense solid-phase weld seam under the tool’s pressure. Friction Stir Welding Principle The principle of friction stir welding is similar to conventional friction welding, as it also utilizes friction heat and plastic deformation heat as the heat source for welding. The difference lies in the fact that in the friction stir welding process, a cylindrical or other shaped (such as a threaded cylinder) welding pin is inserted into the seam of the workpiece. Through the high-speed rotation of the welding head, it is brought into frictional contact with the material of the workpiece, thereby raising the temperature and softening the material at the joint. At the same time, material is subjected to stirring friction to complete the welding. Advantages of Friction Stir Welding 1.The microstructure changes in the heat-affected zone of the welded joint are minimal. Residual stresses are relatively low, and the welded workpiece is less prone to deformation. 2.High efficiency (capable of completing longer weld seams, large cross-sections, and welding in different positions in a single operation). 3.Convenient operating process (enabling mechanization and automation, simple equipment, low energy consumption, high efficiency, and low requirements on the working environment). 4.Low cost (no need for welding wire, no pre-deoxidation of aluminum alloys, and no need for shielding gas when welding). 5.Suitable for welding heat-crack-sensitive materials and for welding dissimilar materials. 6.Welding process is safe, pollution-free, smoke-free, and radiation-free. Disadvantages of Friction Stir Welding…