As a crucial component for thermal management in battery system, the water-cooling plate profoundly influences the safety and lifespan of the battery system.

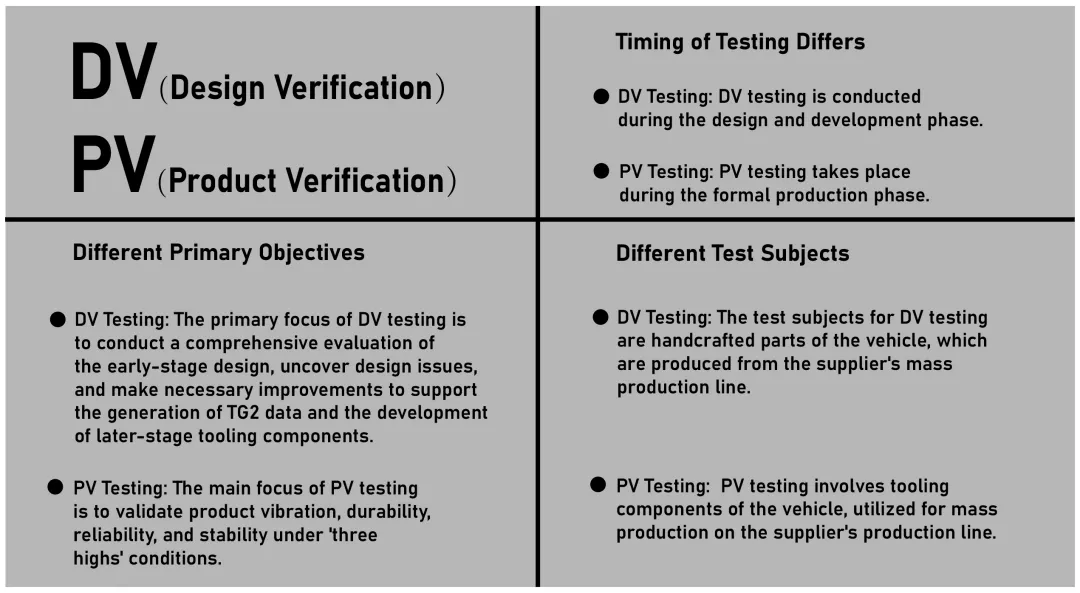

So Yes, DV and PV tests are essential to ensure water-cooling plates meet stringent thermal management standards. These tests validate design reliability and production consistency, minimising risks in product development.

There has been a time in the industry where there was a major failure due to improper testing during development. Ensure robust testing detects defects early so they can be corrected before mass production.

How to Optimise the DV and PV Testing Process?

A streamlined testing process reduces time-to-market and ensures products meet quality expectations. Optimisation is key to efficient project delivery.

Collaborate with experienced suppliers who offer testing expertise, such as XD THERMAL. Efficiently managed testing reduces costs and accelerates timelines.

XD THERMAL Can Perform DV and PV Tests

Structural simulation (Partial View)

- 1. Modal analysis

- 2. Bolt mounting point static/dynamic stiffness

- 3. Random Vibration GB 38031-2020

- 4. Vibration fatigue simulation GB/T 31486

- 5. Mechanical Shock ISO 19453-2020

- 6. Drop

- 7. Bottom scraping

- 8. Cover plate pressure resistance

- 9. Expansion Force

Thermal Simulation (Partial View)

- 1. Cooling Plate Pressure Drop

- 2. Temperature insulation Performance

- 3. Heat exchange test

- 4. Thermal insulation performance

- 5. Parking Temperature insulation Performance

- 6. Low temperature slow charging

- 7. High/low/room temperature fast charging

Product Verification Tests (Partial View)

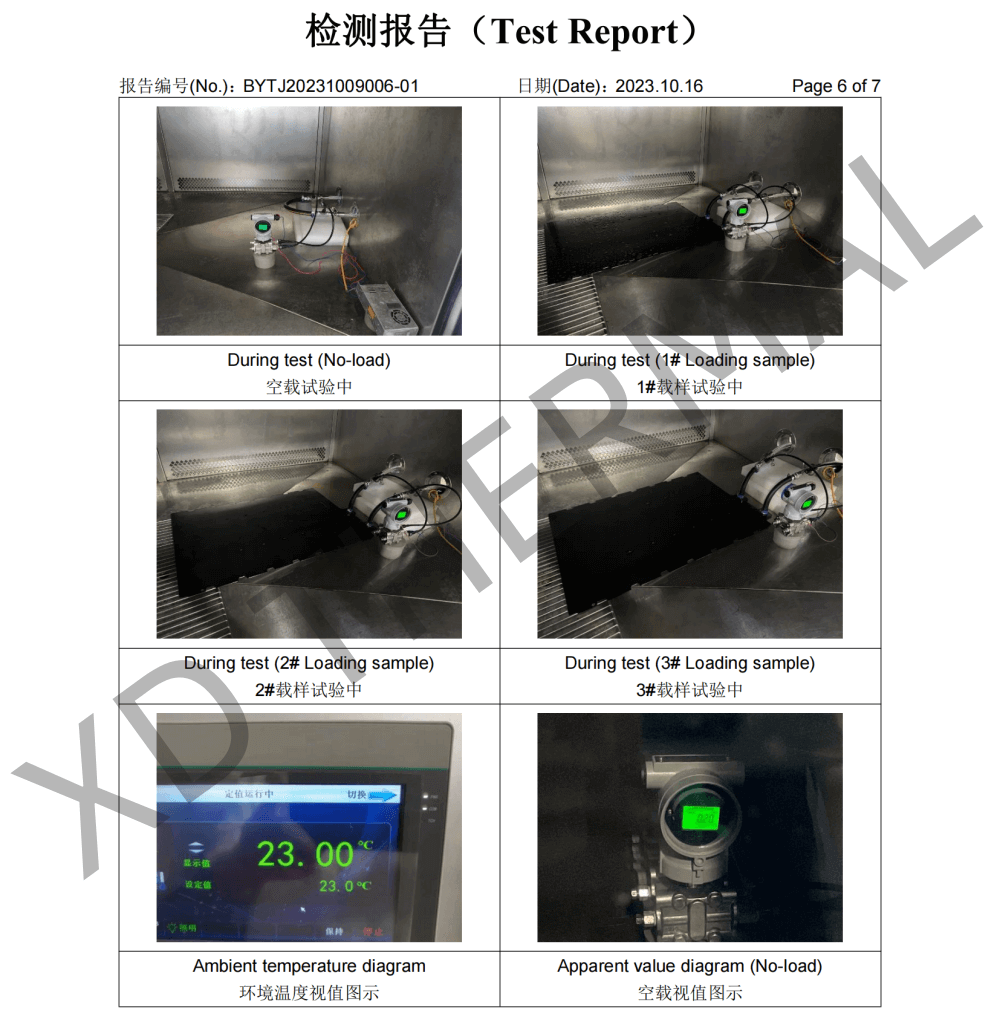

- 1. Cold plate Leakage test

- 2. Pressure drop test

- 3. Burst test

- 4. Vacuum test

- 5. Constant high temp and high humidity test

- 6. Coolant temperature cycling

- 7. Mechanical shock

- 8. Vibration

- 9. Pressure pulsation

- 10. Coolant Compatibility

- 11. Thermal shock

- 12. HIPOT Test

- 13. Dimension check

- 14. Internal technical cleanliness

An experienced supplier will have a well-established SOP (Standard Operating Procedure) for DV and PV testing, along with state-of-the-art facilities. They should offer end-to-end services, from design assistance to mass production. XD THERMAL’s extensive experience in international OEM projects and full-service supplier capabilities make us an ideal partner for comprehensive testing and production needs.