Designing an electric vehicle (EV) battery pack is like orchestrating a carefully balanced symphony: the cells must deliver high power, long cycle life and safety, while the thermal management system must keep them within a narrow temperature band. One component at the heart of this thermal orchestra is the serpentine liquid cooling tube. These extruded metal channels snake through a module, hugging the curvature of cylindrical cells and carrying coolant that absorbs waste heat. In my engineering projects I’ve found that choosing the correct tube shape and size is critical; too small and the cells overheat, too large and you waste space, mass and cost. This guide explains how I match serpentine tubes to three cell sizes—18650, 4680 and 4695—by combining fundamental cell physics with real world manufacturing constraints.

The overview above explains what a serpentine cooling tube is and hints at how sizing works. The rest of this article dives deeper: we explore why serpentine tubes matter, how to size them for each cell format, what material and manufacturing options exist, and which design trade offs engineers and product buyers should consider. Each section answers a specific question so you can jump to the topic most relevant to you.

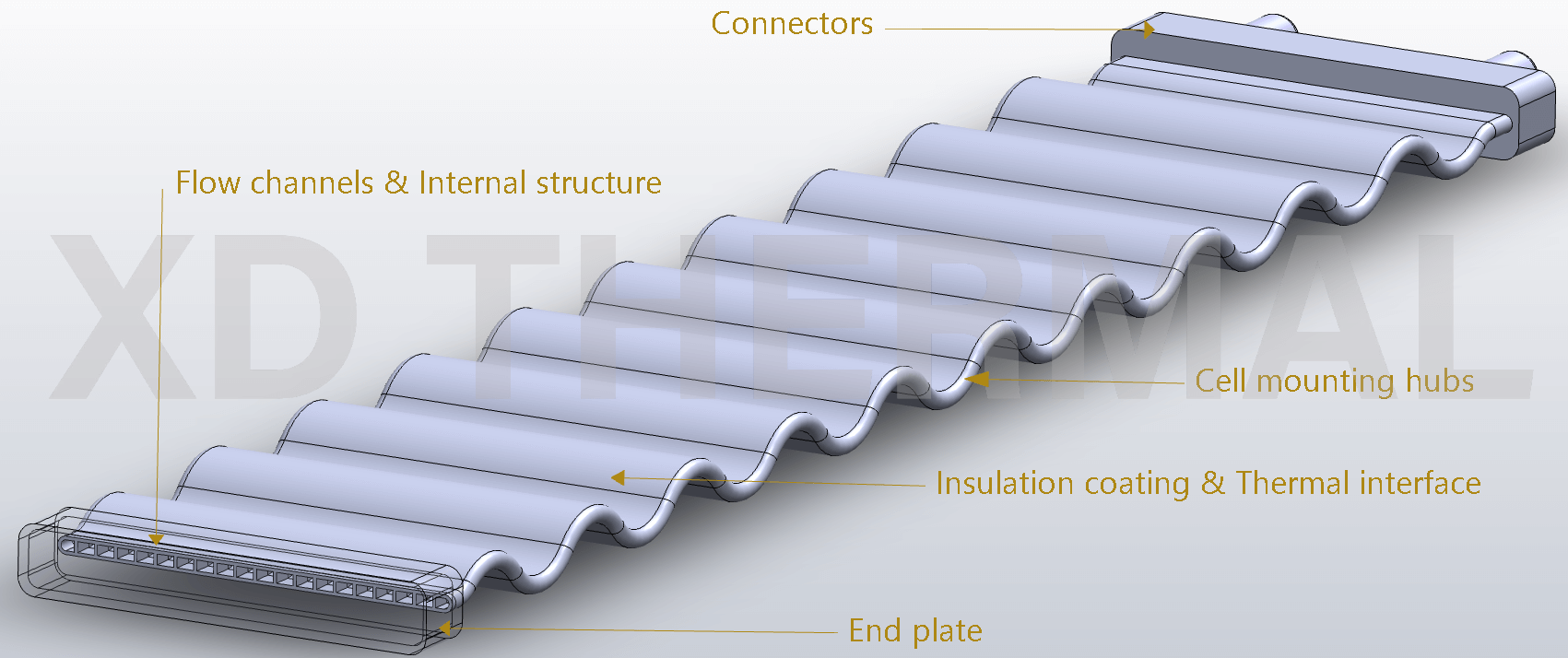

At first glance, a serpentine cooling tube(liquid‑cooling tube) looks like a long, flat ribbon of metal—between cells in a battery module. It is typically made from a high manganese aluminium alloy or sometimes copper, chosen for high thermal conductivity, corrosion resistance and low weight. The extrusion process forms longitudinal microchannels inside the tube; coolant flows through these channels, entering at one end and exiting at the other. The outer walls are curved to fit snugly against cylindrical cells so that a large contact surface is available for heat exchange.

In XD Thermal, these tubes provide “optimal internal structure” for increased heat dissipation, multiple external forms to fit different pack layouts (tubes are offered in straight, U‑shaped or multi‑ribbon designs), accurate workmanship for good contact, and they are 100 % helium leak tested. Their lightweight, corrosion resistant aluminium alloy ensures a 10 year lifetime and makes them recyclable.

The extruded ribbon hugs the curved sides of cylindrical cells, ensuring intimate contact. Early EV battery packs used straight pipes that only touched a cell’s tangent, but serpentine tubes weave between cells for much greater contact area.

Multiple parallel channels inside the extrusion increase internal surface area so the coolant can absorb more heat per unit length. One or two rows of cells are typically placed between consecutive serpentines to expand the heat exchange area

Manufacturers offer straight C2P (cell to pack) tubes, bent C2M (cell to module) tubes and tri-way tubes with three parallel ribbons. C2P tubes are the most popular because they align well with 4680 and 4695 cells and minimise welding joints

In essence, a serpentine tube functions as a long, flat heat exchanger tailored to the geometry of cylindrical cells, balancing thermal performance with packaging constraints

As EV manufacturers chase higher energy density and lower cost, they are adopting larger cylindrical cells in recent years. Tesla pioneered the jump from 18650 (18 mm diameter, 65 mm height) to 21700 (21 mm × 70 mm) and then to 4680 (46 mm × 80 mm) to reduce part count and cost. BMW and Samsung are now introducing 4695 (46 mm × 95 mm) and even longer 46120 formats. While larger cells store more energy and simplify module assembly, they create thermal challenges because a cell’s surface area does not scale with its volume.

| Cell size |

Diameter × height(mm) |

Total area/volume ratio | Side area/volume ratio |

| 18650 | 18 × 65 | 25.3 % | 22.22 % |

| 21700 | 21 × 70 | 21.9 % | 19.05 % |

| 4680 | 46 × 80 | 11.2 % | 8.70 % |

The comparison shows that total area-to-volume ratio drops from 25.3 % for a 18650 cell to 21.9 % for a 21700 and just 11.2 % for a 4680 cell. The side area-to-volume ratio, which governs radial heat dissipation, falls from 22.22 % (18650) to 8.7 % (4680). In other words, a 4680 cell has roughly half the surface area per unit volume of a 18650; the bigger cell therefore generates more heat per unit surface when charged or discharged at similar C rates

The new 4695 cell amplifies this challenge. Samsung’s press release on 31 March 2025 notes that 4695 batteries measure 46 mm in diameter and 95 mm in height and are about six times larger in energy capacity than the earlier 21700 cells. The 4695 can deliver around 20 % higher energy density and 30 % faster charging than BMW’s previous generation, according to XD Thermal’s analysis of BMW’s pack design. With such large energy throughput, heat generation increases and the surface to volume ratio shrinks further. Serpentine tubes with wider and taller profiles are therefore necessary to maintain safe temperatures and prevent thermal run away.

Choosing the correct serpentine tube isn’t a guessing game; it’s a calculated decision based on cell geometry, pack layout, thermal load and manufacturability. When I start a design, I gather all these parameters and then reference manufacturer tables for recommended sizes. I also consider how the tube will be routed within the module and what the pressure drop through the micro‑channels will be. A systematic approach reduces risk and improves pack performance.

Key parameters include width, height, rib thickness and curvature. Width sets how many cell faces and micro‑channels fit; height affects coolant volume and stiffness. Rib thickness ensures mechanical strength and burst pressure; curvature must match cell diameter.

Manufacturers such as we, XD Thermal provide a dimension table to guide these choices. For each cell size, they specify ranges for extrusion height, width, rib thickness, wall thickness and corner radius. Using these ranges as a starting point, we tailor the design by analysing the module geometry, required heat flux and allowable pressure drop. Computational fluid dynamics (CFD) simulations and bench tests then validate whether the chosen tube maintains cell temperatures within the target window (usually 20–40 °C) during high-power charging and discharging. These parameters collectively define the tube’s heat transfer capacity and pressure drop, so balancing them is crucial for effective cooling in real systems.

Cooling tubes for 18650 cells typically have an extrusion height between 2.2 and 3.2 mm and a width between 48 and 50 mm. The rib thickness ranges from 0.28 to 0.43 mm and the wall thickness is 0.25–0.8 mm. The radius of curvature is 1.1–1.6 mm, ensuring good contact with the 18 mm cell.

Because 18650 modules pack many cells closely together, serpentine tubes are often arranged in two parallel ribbons (tri-way tubes are rarely used for this size). With proper thermal interface material between the tube and cells, these dimensions are sufficient to keep cell temperature rise within a few degrees Celsius at typical EV discharge rates. In air-cooled consumer electronics (laptops, power tools), active liquid cooling is usually unnecessary because the 18650’s small size allows convective heat dissipation.

A 4680 cell is 46 mm in diameter and 80 mm high—roughly seven times the volume of a 18650 cell. Its surface area-to-volume ratio is just 11.2 %, so heat must travel farther inside the cell before reaching the surface. To address this challenge, serpentine tubes for 4680 modules are wider and can incorporate more channels. XD Thermal recommends an extrusion width of 65–75 mm and a height of 2.2–3.6 mm. Rib thickness increases to 0.30–0.60 mm to handle higher clamping forces and coolant pressures. If your module is space‑constrained, you might start at the lower end of the width range. For a high‑power racing application, you could go to the upper end and perhaps increase the tube height for more coolant volume.

For 4680 modules, I favour C2P straight tubes. These U-shaped loops have inlets and outlets at the same side, reducing the number of welds and making assembly easier. They also allow two rows of 4680 cells to be sandwiched between adjacent tubes, increasing contact area and promoting uniform temperaturesengineeringcheatsheet.com. Thermal interface materials (silicone pads or gap fillers) fill any voids between the tube and cells, preventing hot spotsxdthermal.com. In high power applications, I sometimes combine side serpentine cooling with bottom heat spreaders or immersion cooling to further reduce temperature gradients. Don’t forget to factor in manufacturing tolerances and assembly requirements—tubes must align with cells and be easy to weld to inlet/outlet manifolds

The 4695 cell is the newest entrant in the 46-series family. Samsung SDI’s 2025 press release confirms that 4695 batteries measure 46 mm in diameter and 95 mm in height and are assembled into modules for micro-mobility and EV customerssamsungsdi.com. Because of its increased length, the 4695 has a still lower area-to-volume ratio than the 4680 and can deliver roughly six times the energy of a 21700 cells. BMW’s 4695 modules claim 20 % higher energy density and 30 % faster charging than earlier BMW packs.

To manage this heat, I select even wider tubes—75–85 mm in width—and a height of 2.2–3.8 mm. Rib thickness remains 0.35–0.60 mm, and the radius of curvature grows slightly to 1.1–1.9 mm to fit the longer cell. These tubes may have more microchannels to increase coolant flow area, and the module design often uses tri-way cooling tubes or additional bottom plates to ensure uniform temperature along the cell’s extended length. Because the 4695 generates more heat during fast charging, I pay special attention to coolant flow rate and pressure drop. Simulation helps identify the optimal flow distribution; sometimes a serpentine tube alone is insufficient and must be supplemented with pack-to-open-body (PTOB) cooling structures—large plates integrated into the pack floor. BMW’s design uses such PTOB integration to ensure more effective cooling than Tesla’s cell-to-chassis approach.

Material choice is more than an engineering detail; it affects weight, cost, thermal performance and corrosion resistance. In my designs, I often choose high‑manganese aluminum alloys, which deliver lightweight, good thermal conductivity and corrosion resistance.

Most serpentine tubes are made from aluminum alloys like 3003, 3005, 6061 or 6063. High‑manganese content improves corrosion resistance. Suppliers also offer copper tubes, which provide better thermal conductivity but add weight and cost. Regardless of material, tubes undergo anodizing or conversion coatings to prevent galvanic corrosion. High‑frequency welding helps achieve thin walls. Choosing the right alloy ensures durability and thermal performance and reduces long‑term costs and energy losses for EV owners.

In addition to the base metal, manufacturing processes influence performance. XD Thermal uses extrusion followed by precision machining, welding and helium leak testing to ensure reliability. And micro‑channel tubes use high‑frequency welding to join the extrusion to the header pipes. These processes achieve thin walls (0.25–0.8 mm) while maintaining burst pressures of 1 MPa or more. When specifying a tube, I also consider the coolant’s chemistry; a water‑glycol mixture is common, but some packs use refrigerants like R134a. Compatibility with coolant additives influences material selection and coating. Always ask for supplier test reports and certificates to ensure quality.

Cooling is just one piece of the thermal management puzzle. Engineers and product buyers must consider coolant selection, flow rates, pressure, integration, and safety. A poorly designed thermal system can shorten battery life, reduce performance, and even lead to dangerous failures. A holistic approach is needed to ensure that the cooling tubes we choose work in harmony with the rest of the packaging.

Key considerations for thermal management include:

● The coolant type (water‑glycol mixtures or refrigerants) —— Most EVs use a water glycol mixture as coolant, sometimes mixed with corrosion inhibitors. Some systems use refrigerants (e.g., R134a) for direct expansion. The coolant’s thermal properties influence tube sizing and pump selection.

● operating pressure (1–3 bar) and flow rate —— Engineers should use thermal interface materials to fill air gaps and improve contact. Integration with bottom plates or structural enclosures enhances cooling. Safety tests—helium leak, vibration and corrosion checks—ensure reliability. Good design also includes heaters for cold weather and sensors to monitor temperature. Simulation and real‑world tests verify temperatures stay within safe limits. Regular maintenance and adherence to evolving regulations further ensure safety and performance.

● Thermal interface materials —— Engineers should use thermal interface materials to fill air gaps and improve contact. Even with well designed tubes, microscopic gaps between the tube and cells can create thermal resistance. Silicone pads, graphite sheets or phase-change materials fill these gaps and improve heat transfer.

● Integration with pack —— For 4680 and 4695 packs, bottom plates, side plates and modules are often part of a pack-to-open-body design. This architecture uses the vehicle’s chassis as a heat sink and allows serpentine tubes to be integrated with structural members.

● Safety tests(helium leak, vibration and corrosion checks) —— This involves both keeping cell temperatures low and designing barriers to contain fires. Many EV OEMs require that cooling tubes maintain integrity for at least 10 years and pass stringent vibration and leakage tests.

Beyond serpentine tubes, thermal management includes heaters for cold weather preheating, sensors for temperature monitoring and algorithms for balancing current. Flow rate is crucial; high flow reduces temperature gradients but increases pump power and system complexity. Engineers must also design for serviceability—ensuring that tubes and coolant lines can be accessed and replaced if necessary. Regulatory requirements continue to evolve; new standards may dictate maximum allowable temperature rise or require additional containment features. By staying informed and working closely with suppliers, engineers can design systems that meet performance, safety and cost goals.

Choosing the right serpentine liquid cooling tube is fundamentally about matching the tube’s geometry and material to the size and thermal load of the battery cells. Small 18650 cells (18 mm × 65 mm) work well with narrow tubes (≈48–50 mm wide) because their surface area-to-volume ratio is highxdthermal.com. Larger 4680 cells (46 mm × 80 mm) require wider tubes (65–75 mm) and thicker ribs to manage the greater heat load. The newest 4695 cells (46 mm × 95 mm), which deliver six times the energy of 21700 cells, demand even wider tubes (75–85 mm) and sometimes supplementary cooling plates. Material selection (high-manganese aluminium vs. copper), tube geometry (C2P, C2M, tri-way), and integration with the pack architecture further refine the design. Ultimately, careful analysis, simulation and testing ensure that the chosen serpentine tube keeps cells cool, safe and performing at their best. By following the guidelines presented here and validating designs with simulation and testing, engineers and buyers can build safer, longer‑lasting EV batteries packs.