Solar panels are well known to most people—they are clean, renewable, and can directly convert sunlight into electricity, making them an ideal source of green energy in people’s eyes. However, in real-world applications, I’ve noticed a problem that is often overlooked—the hotter the solar panel gets, the lower its power generation efficiency becomes. This is especially true during hot summers or in regions where temperatures are already high, as the surface temperature of the panel can easily rise to sixty or even seventy degrees Celsius. At that point, its power output is essentially being “discounted.” So how can this problem be addressed? One effective solution is to use liquid cooling solar panel. By allowing coolant to circulate and remove excess heat in time, they help keep the panel at an ideal operating temperature, thereby improving overall power generation efficiency.

At this point, some might ask: how exactly does a solar panel liquid cooling system work? And can it really bring noticeable improvement? Actually, the principle isn’t complicated. A liquid cooling system sets up cooling channels on the back of the solar panel, allowing coolant to flow continuously and carry away the accumulated heat. Compared to natural heat dissipation, it provides more active and efficient temperature control—especially under scorching weather, where its advantages become even more apparent.

From what I’ve learned, experimental data shows that using a liquid cooling system—meaning a liquid-cooled solar panel—can reduce operating temperatures by 10°C or even more. And this seemingly small temperature difference brings real benefits: for every 1°C drop, power generation efficiency can improve by about 0.4% to 0.5%. From a single panel to an entire photovoltaic array, the cumulative gain is quite substantial.

For example, one experimental study in Europe tested 50 Wp and 310 Wp monocrystalline modules and found that with liquid cooling, panel temperatures dropped by about 29°C, and output power increased by more than 11%. In a field test conducted in Giza, Egypt, researchers used rear-side water spraying to bring panel temperatures down from 65°C to 42°C, resulting in an 18% increase in output power. These results clearly show that the performance boost from liquid cooling under real conditions is measurable.

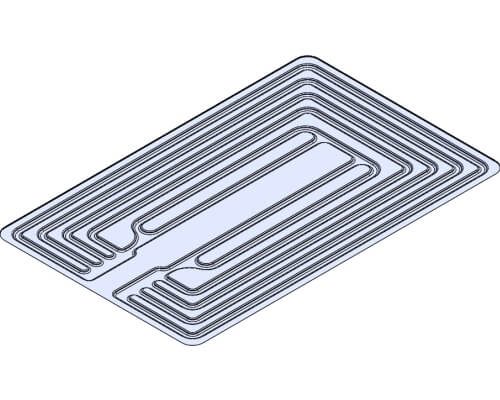

For a liquid cooling system to truly be effective, the key lies in how it is designed and applied. Take a recent case I came across—it involved installing a liquid cooling plate tightly attached to the back of a solar panel, with multiple internal flow channels. The coolant enters from one side, flows evenly across the back of the panel while continuously absorbing heat, and then exits from the other side, completing a full cooling cycle. In demonstration projects in parts of Europe and Poland, similar structural designs using liquid cooled PV modules showed an average efficiency increase of over 10%, along with strong engineering feasibility and a payback period of less than ten years.

Another advantage of this structure is that it can remove heat directly from the back of the solar panel without affecting the front-side light absorption or damaging the original structure. The coolant flows right along the areas where heat tends to accumulate, essentially adding a layer of active cooling protection to the solar panel, making the temperature control more effective.

Another design that I find quite clever is that it can make use of open water sources, such as river or lake water, to create a cooling loop using natural water pressure or height differences—without the need for additional power. For projects located near natural water bodies, this approach is not only energy-saving but also convenient for long-term operation.

Once the temperature is stably controlled, the photoelectric conversion efficiency of the solar panel is naturally better guaranteed. Especially in high-temperature or strong sunlight environments, this kind of liquid cooling structure not only improves power generation performance but also makes the overall system run more steadily and reliably.

Besides cooling, the role of liquid cooling technology in improving the efficiency of photovoltaic modules goes far beyond that. It acts more like a comprehensive optimization approach—enhancing the overall performance of the photovoltaic system from multiple angles, including temperature control, system stability, and long-term reliability. I’ve summarized a few key points that I think are especially important:

✅ Improved temperature stability for more consistent power generation

The continuous flow of coolant is not just for cooling—it’s more importantly to keep the panel within a stable operating temperature range. Avoiding frequent temperature fluctuations helps reduce efficiency swings and ensures steady system output.

✅ Slower material aging and improved component reliability

Long-term high-temperature operation is one of the key factors leading to efficiency degradation in photovoltaic modules. A liquid cooling system can effectively reduce thermal stress on encapsulation materials and solder joints through continuous temperature control, slowing the aging process and extending the high-efficiency life cycle of the components.

✅ Reduced risk of local overheating and better system consistency

Especially in large photovoltaic arrays, local overheating can drag down the performance of the entire string. A liquid cooling system helps maintain uniform temperatures, reduce efficiency mismatches caused by temperature differences, and improve the system’s overall output efficiency.

✅ Heat recovery to improve overall energy utilization

The heat carried away by the coolant is not wasted. Some projects have already begun using this thermal energy for heating domestic water, industrial preheating, or agricultural greenhouses, achieving a “power + heat” synergy and further enhancing overall system efficiency. For example, in photovoltaic-thermal (PVT) systems deployed in several countries, liquid cooling technology not only improves panel efficiency but also captures additional thermal energy. In some cases, the total solar energy utilization rate has reached as high as 75%, significantly increasing overall energy efficiency.

✅ Assisted cleaning for better light absorption

If the system is properly designed, the flowing coolant can also help remove dust or pollutants during circulation, reducing shading effects. This is especially useful in dusty or arid regions, indirectly improving light absorption and power generation performance.

All in all, liquid cooling technology is not just about “cooling down” solar panels. It improves photovoltaic thermal performance from multiple angles—not only making power generation more stable, but also extending the lifespan of the equipment, and even enabling heat recovery and assisted cleaning. Its advantages become especially clear in high-temperature regions or in projects with high demands for power generation efficiency.

In the future, as the scale of photovoltaic power generation continues to grow, technologies like liquid cooling—which balance both performance and sustainability—are sure to attract increasing attention. I hope this sharing provides you with some insights and inspiration in understanding the application value of liquid cooling solar panels.