Bewertungen von Kunden

Was haben unsere Kunden zu sagen?

Sie haben von Anfang an verstanden, worum es uns geht und was wir brauchen. Ihr Team ist am Ball und sehr hilfsbereit. Sie melden sich immer, um sicherzustellen, dass alle Fragen oder Sorgen, die wir haben, geklärt werden. Einfach großartig!

Graham SterlingChefingenieur Maschinenbau

Jeder Vorschlag, den sie machen, zeigt, dass sie nicht nur an den Verkauf denken, sondern daran, Grenzen zu überschreiten und gemeinsam etwas Neues und Wertvolles zu schaffen.

Benedikt HawthorneManager für strategische Beschaffung

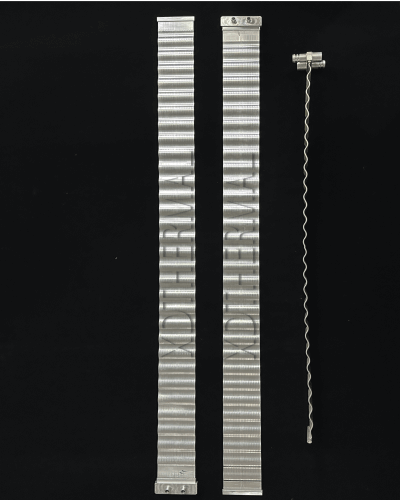

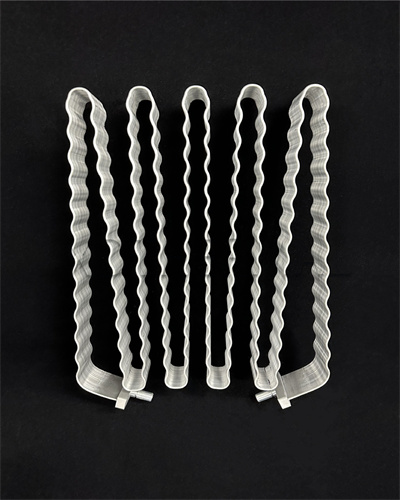

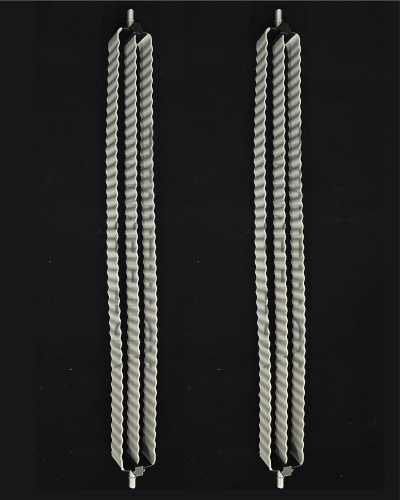

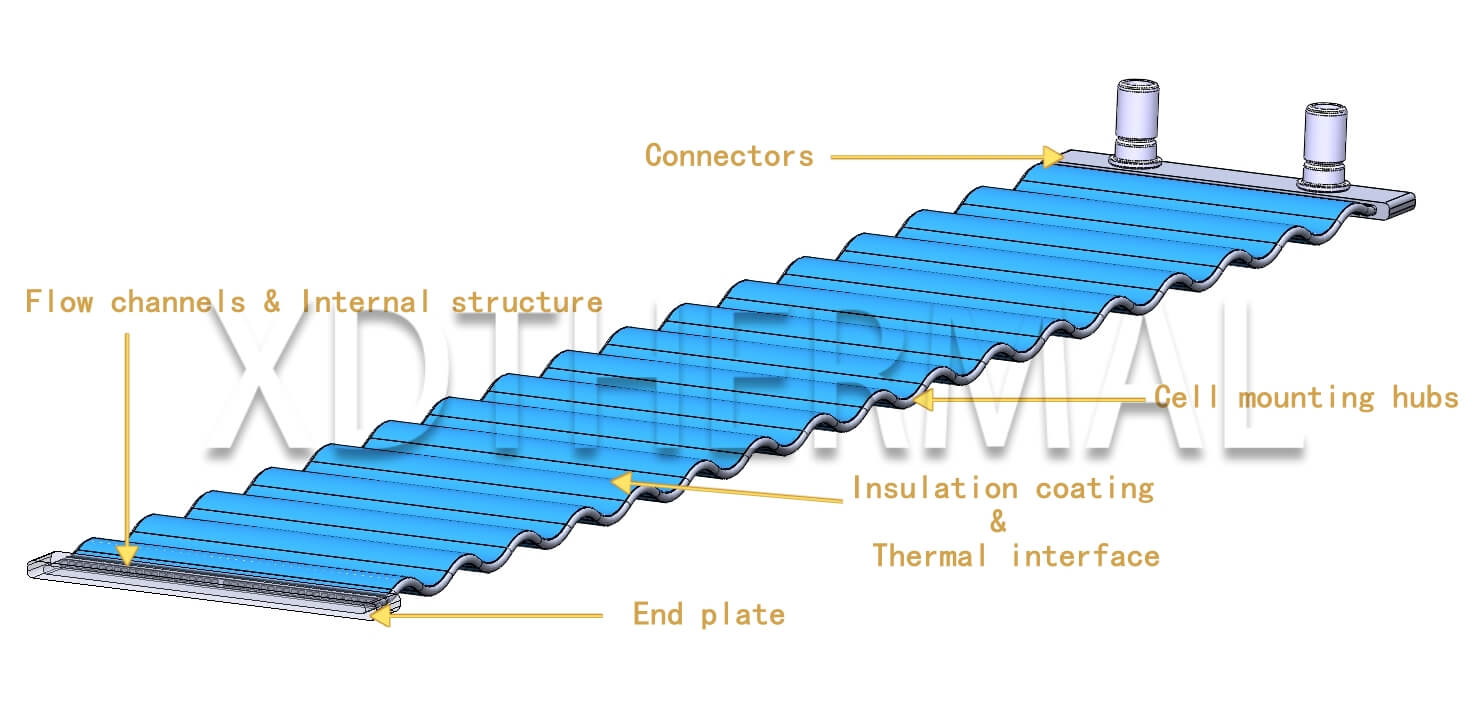

Ihre Transparenz während des Verlaufs der Flüssigkühlungsrohr-Projekte hat unser Vertrauen und unseren Respekt für sie gestärkt.

Leo GrantEV Cooling Solutions Beschaffungsingenieur