What is the price range of high-quality micro-channel liquid cooling plates?

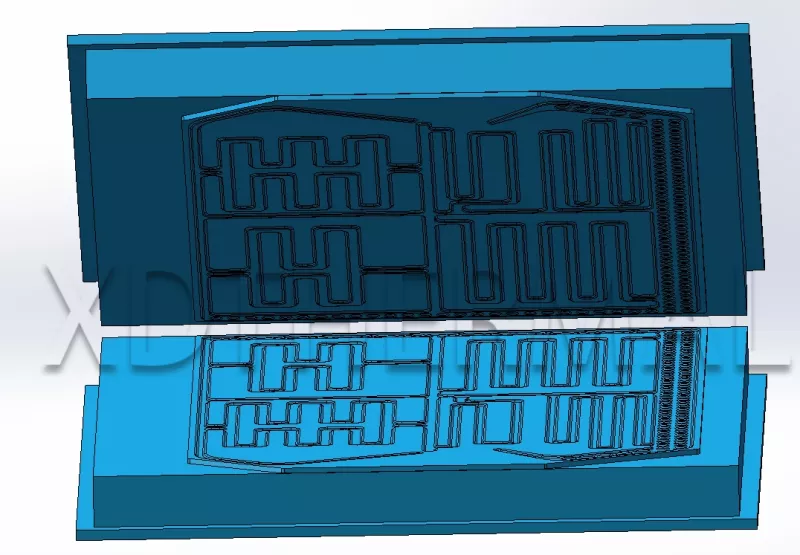

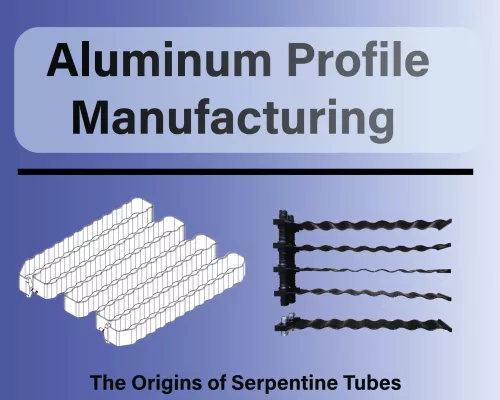

What is the price range of high-quality micro-channel liquid cooling plates? Having trouble figuring out how much these premium micro-channel liquid cooling plates cost? It can be frustrating because a lot of these companies don’t give the pricing upfront, and you want to know how much this stuff costs, especially when quality is important and performance is required for the projects you’re doing. High-quality micro-channel liquid cooling plates typically range from $30 to $150 per unit. This price varies based on materials used, manufacturing processes, order quantities, and the expertise of the supplier. The bottom line is you need to know how much it’s going to cost. So, we need to dive further into what all leads to these costs. Table of Contents What are the key factors influencing the price of micro-channel liquid cooling plates? Multiple factors contribute to the price of this stuff. It’s not going to be the same every single time, and talking about “Hey, what do these things cost?” is not a one-size-fits-all answer. Factors such as material selection, production techniques, order volume, and supplier capabilities significantly impact the overall cost of these advanced cooling solutions. The choice of materials—aluminum or copper—makes a big difference in the price. How you build it—vacuum brazing, hydro forming, special processes for Micro Channel Heat Exchangers (also called Micro Channel cold plates)—all those things make a difference in the price. The quantity you order also makes a difference in the price because of economies of scale. What is the quality control process for micro-channel plates? Quality control is critical for the reliability, performance, and safety of micro-channel cold plates in applications like electric vehicles (EVs) and energy storage systems (ESS). You perform a variety of different quality control inspections all along the way including inspection of all the material coming in, inspection of runners, production of all of the different…