Can BMW’s Large Cylindrical Batteries Overcome Tesla’s Challenges?

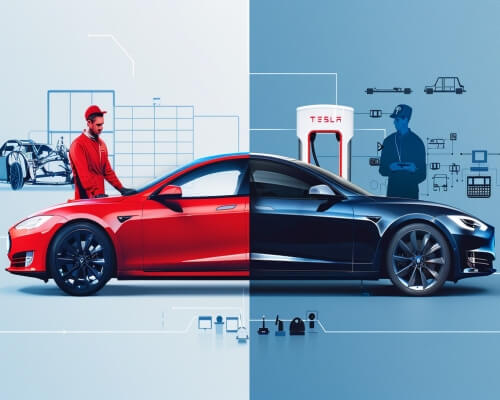

Can BMW’s Large Cylindrical Batteries Overcome Tesla’s Challenges? Tesla’s 4680 battery technology was meant to revolutionize EVs, yet production challenges have stalled its success. Meanwhile, BMW is betting big on its large cylindrical batteries. But can it succeed where Tesla struggles? And how crucial is thermal management in this race? Battery technology is more than just higher energy density—thermal management and safety are critical. Heat buildup reduces battery lifespan, impacts charging speed, and can even cause thermal runaway. Efficient cooling solutions, like liquid cooling plates and battery enclosures, are essential for maintaining performance and longevity. Companies specializing in EV battery thermal management, such as XDTHERMAL, provide advanced cooling solutions that help maximize battery efficiency and safety. Table of Contents Tesla vs. BMW: A Comparison of Large Cylindrical Battery Strategies To better understand why BMW may succeed where Tesla struggles, we can compare their approaches to large cylindrical batteries: Feature Tesla (4680 Battery) BMW (4695 & 46120 Batteries) Manufacturing Process Dry electrode coating (causing high production failure rates) Wet electrode coating (more stable, proven technology) Energy Density Increase 5x higher than older Tesla batteries 20% higher than BMW’s previous generation Charging Speed Claimed to be significantly faster, but lacks real-world results 30% faster charging than BMW’s previous batteries Thermal Management Approach Uses a cell-to-chassis (CTC) design, limiting cooling options Uses a pack-to-open-body (PTOB) design, allowing more effective cooling Production Challenges Struggles with high failure rates in dry-coating and cell expansion issues Collaborates with CATL & EVE Energy, ensuring stable production Battery Safety Concerns High heat buildup due to compact battery integration Focus on long-term thermal stability and safe energy output Scalability Production is significantly behind schedule Already ramping up for 2025 mass production Supply Chain Heavy internal production reliance Outsources to major battery suppliers for efficiency From this table, it’s clear…