고객 리뷰

고객의 의견은?

처음부터 저희의 목적과 필요한 것을 잘 파악하고 있었습니다. 팀원들은 항상 저희의 궁금증이나 걱정이 해결될 수 있도록 최선을 다해 도와주고 있습니다. 정말 훌륭해요!

그레이엄 스털링수석 기계 엔지니어

그들이 제안하는 모든 것은 그들이 단순히 매출만을 생각하는 것이 아니라 한계를 뛰어넘어 새롭고 가치 있는 무언가를 함께 만들어내고자 한다는 것을 보여줍니다.

베네딕트 호손전략 소싱 관리자

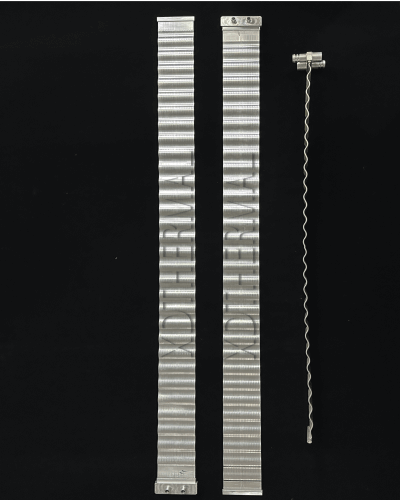

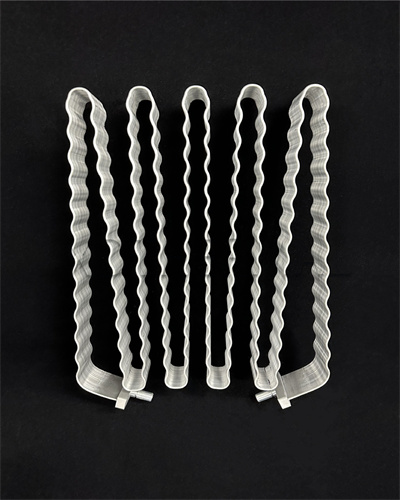

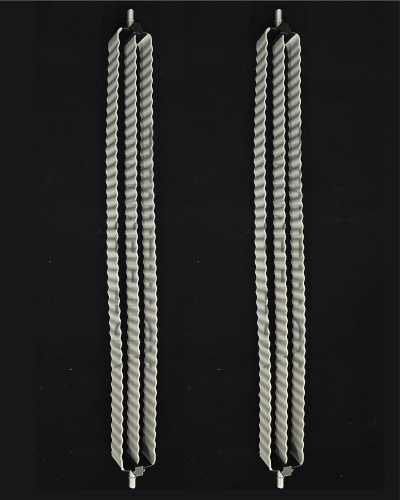

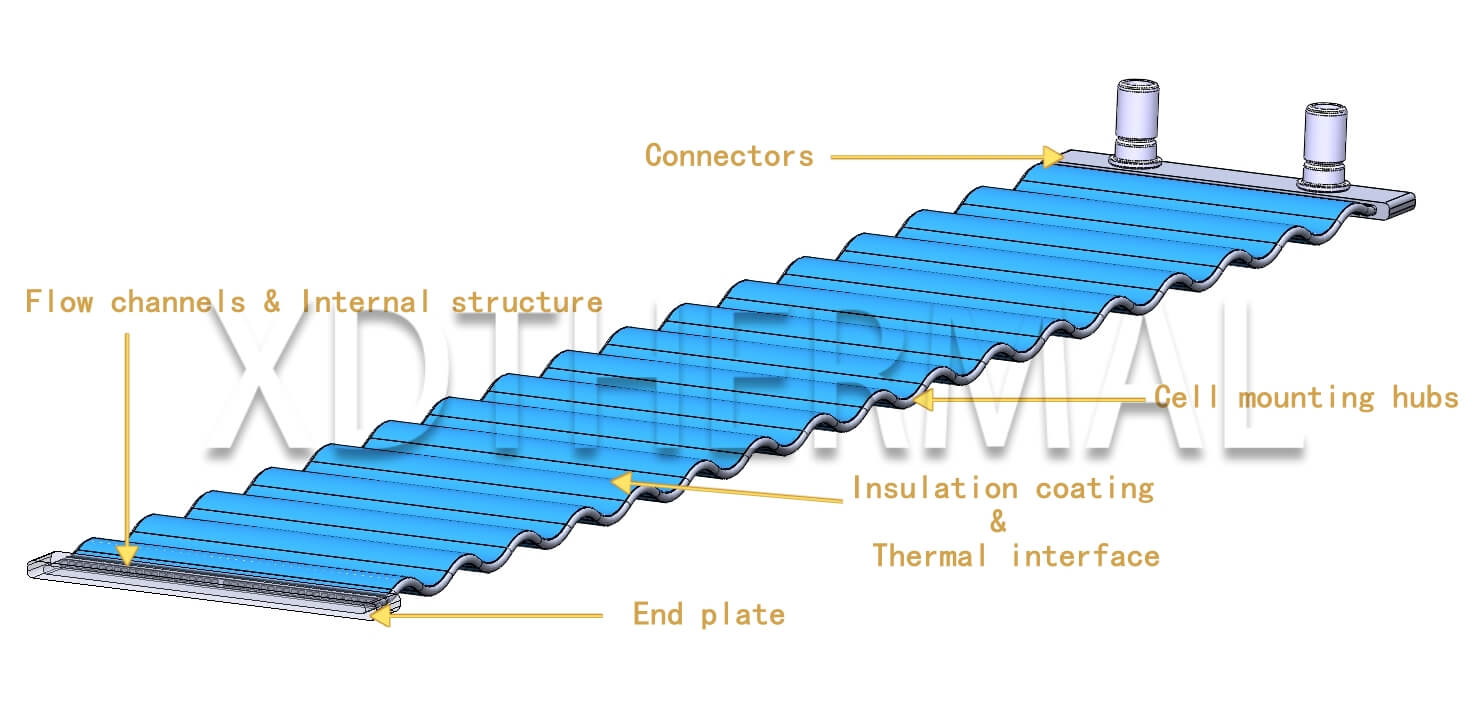

액체 냉각관 프로젝트가 진행되는 동안 그들의 투명성은 우리의 신뢰와 존경을 더욱 높여주었습니다.

레오 그랜트EV 냉각 솔루션 조달 엔지니어