En los últimos años, la demanda de tubos de refrigeración serpentina ha crecido considerablemente, sobre todo en el sector de los vehículos eléctricos (VE). Estos tubos desempeñan un papel fundamental en la gestión térmica de los paquetes de baterías, ya que garantizan que las baterías de iones de litio se mantengan a temperaturas óptimas para evitar el sobrecalentamiento y mejorar el rendimiento. Pero, ¿cómo se fabrican exactamente estos componentes esenciales? El viaje de un tubo serpentín comienza con el proceso de extrusión del aluminio, una técnica avanzada que se ha ido perfeccionando a lo largo de los siglos.

La fabricación de perfiles de aluminio, incluidos los utilizados para los tubos de refrigeración serpentina, consta de varias etapas clave. El proceso comienza con la ajuste del índice de contracción. Cada máquina de extrusión tiene características únicas que influyen en cuánto se contrae el aluminio durante el proceso. Este paso requiere una calibración y unas pruebas precisas, en función del tonelaje de la máquina y de la marca del equipo utilizado.

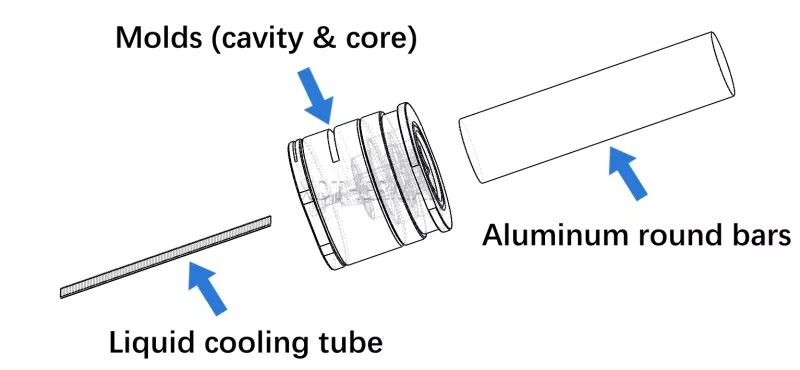

El siguiente paso consiste en calentar y cortar el aluminio. Una barra redonda de aluminio, normalmente del Materiales de las series 3 ó 6se calienta a alta temperatura en un horno. El calentamiento ablanda el metal, lo hace más maleable y lo prepara para la extrusión. Una vez calentada, la barra de aluminio se corta en secciones más pequeñas adecuadas para la máquina de extrusión.

A continuación, las barras de aluminio troceadas se transfieren a la extrusora mediante una máquina de transferencia. De este modo, el material pasa sin problemas a la siguiente fase, sin retrasos ni ineficiencias.

En proceso de extrusión tiene una larga historia, que se remonta a 1797, cuando Joseph Bramah patentó el primer método para fabricar tubos de metal blando. A lo largo de los años, el proceso se ha adaptado y perfeccionado para aplicaciones modernas, como la producción de perfiles de aluminio extruido para industrias que van desde la construcción hasta los vehículos eléctricos. El uso de prensas hidráulicas ha revolucionado el proceso, permitiendo la extrusión de formas complejas con gran precisión, lo que resulta esencial para crear productos como tubos de refrigeración de baterías.

Una vez cortado el aluminio, hay que transferirlo eficazmente a la máquina de extrusión. Para ello se utiliza un sistema transportadorque garantiza un movimiento suave e ininterrumpido de los materiales. El aluminio se prepara y se coloca correctamente antes de entrar en la extrusora, donde se le dará la forma del perfil final.

La extrusión de aluminio es una pieza clave en la creación de tubos serpentina. Una vez que el material entra en la extrusora, se calienta de nuevo hasta fundirse. Bajo una inmensa presión, el aluminio fundido es forzado a atravesar una matriz, que es una herramienta especializada que determina la forma de la sección transversal del producto final. En este caso, la matriz se diseña para crear la exclusiva estructura serpentina necesaria para las aplicaciones de refrigeración de baterías.

Enderezar a menudo es necesario después de la extrusión, ya que la alta presión utilizada durante el proceso puede hacer que el producto se deforme o se doble. A enderezadora alinea el material para cumplir los requisitos dimensionales necesarios. Por último, el aluminio extruido se corte a la longitud deseada en función de las especificaciones del cliente o del uso previsto de los tubos de refrigeración.

La calidad de las materias primas utilizadas en la extrusión de aluminio es fundamental. Barras redondas de aluminionormalmente del Materiales de las series 3 ó 6se seleccionan en función de sus propiedades. Serie 3 de aluminio es más blando y más propenso a las impurezas durante el proceso de extrusión, lo que puede provocar defectos como agujeros en el producto final. Serie 6 de aluminioes más fiable y fácil de trabajar, lo que se traduce en mejores resultados de moldeo y extrusión.

Para mejorar aún más la calidad, máquinas decapadoras puede utilizarse para eliminar las impurezas superficiales de las barras de aluminio antes de que entren en el proceso de extrusión. Este paso es especialmente importante para aplicaciones de alto rendimiento como Tubos de refrigeración de baterías de VECualquier defecto del material puede provocar problemas de durabilidad del producto a largo plazo.

Además, durante el proceso de corte, se pueden eliminar las impurezas del aluminio desechando las cabezas y las colas de las barras redondas, lo que garantiza que sólo se utilice material de la mejor calidad.

El molde, o matriz, utilizado durante la extrusión es uno de los factores más importantes para determinar el éxito del proceso. Estos moldes se fabrican a medida para cada aplicación, con tolerancias estrictas y estructuras complejas para satisfacer las necesidades específicas del cliente.

Para productos como los tubos de refrigeración de baterías, el molde debe diseñarse cuidadosamente para crear la intrincada forma serpentina que permite una gestión térmica eficaz en las baterías de vehículos eléctricos.

La gestión térmica es crucial en las baterías de los vehículos eléctricos, ya que el sobrecalentamiento puede reducir su vida útil y afectar a su rendimiento. Los tubos de refrigeración serpenteantes, fabricados en aluminio extruido, ofrecen una solución eficaz para gestionar el calor. El diseño en serpentín permite un flujo óptimo del refrigerante por todo el pack de baterías, garantizando que cada célula se mantenga a la temperatura ideal.

El uso de tubos de refrigeración líquida es especialmente eficaz en vehículos eléctricos de alto rendimiento, en los que mantener una temperatura constante de la batería es esencial tanto para la seguridad como para la eficiencia. La excelente conductividad térmica del aluminio lo convierte en el material preferido para estos sistemas de refrigeración.

El aluminio ofrece una combinación única de propiedades de ligereza y conductividad térmica, lo que lo convierte en el material perfecto para Tubos de refrigeración de baterías de VE. Su capacidad para disipar el calor rápidamente garantiza que el pack de baterías se mantenga frío, incluso en situaciones de alta exigencia como la aceleración rápida o la conducción prolongada.

Además, el aluminio extruido es altamente personalizable, lo que permite a los fabricantes crear formas complejas como tubos serpentinos, esenciales para una gestión térmica eficaz.

Los orígenes de los tubos de refrigeración de serpentín se encuentran en el sofisticado proceso de extrusión de aluminio, que se ha ido perfeccionando con el tiempo para satisfacer las crecientes demandas de industrias como la de los vehículos eléctricos. Combinando tecnología avanzada con materiales de alta calidad, los fabricantes pueden producir tubos de refrigeración de baterías que garantizan la seguridad y eficiencia de los paquetes de baterías de los vehículos eléctricos.

En el futuro, a medida que los vehículos eléctricos sigan evolucionando, el papel de la extrusión de aluminio en los sistemas de gestión térmica será cada vez más importante. Comprender los entresijos de este proceso ayuda a compradores e ingenieros a tomar decisiones informadas a la hora de seleccionar soluciones de refrigeración para sus productos.

He trabajado en la gestión térmica de baterías durante más de 5 años, ocupándome de muchos proyectos internacionales. Si tiene curiosidad sobre los productos o servicios de refrigeración líquida de baterías, ¡no dude en hacerme cualquier pregunta!