¿Sus proyectos de gran envergadura se ven frenados por obstáculos en la contratación? ¿Tiene dificultades para elegir placas de refrigeración eléctricas soluciones comprar? Hablemos de cómo resolver esos problemas todo lo que necesitas saber para que ese problema desaparezca ahora mismo.

En este artículo se describen los principales riesgos que entraña la compra de estos equipos, a partir de un ejemplo real de éxito. Le muestra cómo XD THERMAL trabajó con un ingeniero de estructuras para eliminar estos riesgos y conseguir que los equipos pesados rindieran más.

La falta de claridad en las especificaciones técnicas es un riesgo que hay que afrontar desde el principio. Sobre todo cuando se trata de las necesidades de alto rendimiento de equipos pesados. Se puso en contacto conmigo un ingeniero de estructuras que trabaja con equipos pesados. Este ingeniero vino con algunas especificaciones preliminares sobre las placas de refrigeración y los cerramientos que necesitaba para la protección térmica de sus aplicaciones. También tenía algunas ideas preliminares sobre el intercambio térmico que necesitaba de nuestras placas.

Aunque el cliente tenía algunos parámetros de diseño, no tenía muy claro qué necesitaba exactamente en cuanto a rendimiento térmico. Hablando con ellos, pudimos asegurarnos de que no iba a haber una gran desconexión entre lo que pensaban que iban a obtener y lo que les suministramos.

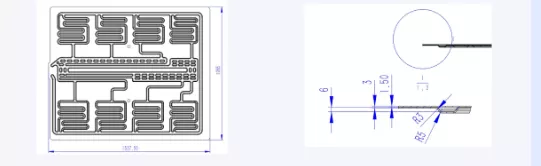

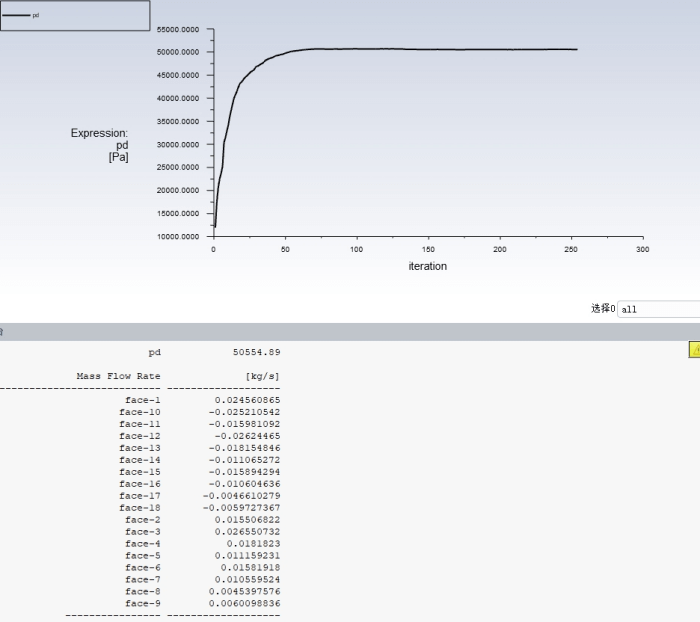

Las limitaciones de espacio en el diseño y las restricciones de fabricación son los riesgos número dos en las aplicaciones pesadas. Basándonos en el trabajo que habíamos realizado en la primera fase, hicimos algunas simulaciones basadas en su diseño para asegurarnos de que nuestras placas de refrigeración intercambiarían suficiente calor en el espacio que tenían disponible para las piezas.

Gracias a una combinación de ajustes en el diseño de los canales de flujo del refrigerante y a la modificación de las dimensiones, conseguimos mejorar el rendimiento con una pieza del mismo tamaño. También nos aseguramos de que pudieran fabricar las placas en su propio taller.

Otro reto con el que suelen encontrarse los profesionales de la contratación es cuando los ajustes técnicos que hay que hacer acaban repercutiendo en el cambio de coste. Proporcionamos un presupuesto detallado y pormenorizado que mostraba exactamente lo que iban a obtener con el diseño actualizado y por qué habían cambiado los costes.

Con más de diez años de experiencia en fabricación en el extranjero, pudimos anticiparnos al futuro y a los retos que podrían tener con la manipulación de materias primas, la gestión de moldes y la coordinación de todos estos talleres en la línea de producción. Nos aseguramos de anticiparnos a todo lo que podía ir mal y pusimos mano de obra con antelación para que hicieran las cosas a tiempo.

Una vez más, debido a las duras condiciones de funcionamiento de estas cosas en la aplicación de servicio pesado, estaban especialmente preocupados por conseguir un montón de chatarra. Les recomendamos que hicieran una Verificación del diseño (DV) y verificación del proceso (PV) prueba a

asegurarnos de que nuestra pieza iba a funcionar como decíamos. Para hacer más riguroso este proceso y reducir el coste para el cliente, realizamos inspecciones completas durante la fase de muestra. Después, pasamos a las inspecciones por muestreo una vez que estábamos en la fase de producción en serie.

En el segmento de la logística, la reserva y el envío son los principales puntos de riesgo. En un principio, el cliente quería utilizar su propio proveedor logístico, pero el departamento de logística se vio desbordado durante un periodo de gran volumen de reservas. Esto provocó retrasos tanto en las reservas de contenedores como en los calendarios de envío.

Para garantizar el avance puntual del proyecto, XD THERMAL actuó con rapidez coordinándose con su equipo interno de logística. Mediante una gestión proactiva, ayudamos con éxito en el proceso de envío y garantizamos que la mercancía se entregara a tiempo, evitando posibles retrasos en el proyecto.

La asistencia posventa desempeña un papel crucial en el éxito de cualquier proceso de adquisición, especialmente en aplicaciones de servicio pesado en las que el rendimiento de las placas de refrigeración es fundamental para la eficacia operativa. Tras la entrega, XD THERMAL mantuvo contactos regulares con el cliente para asegurarse de que las placas de refrigeración funcionaban como se esperaba.

También proporcionamos asistencia técnica continua, respondiendo a las preguntas del cliente y abordando posibles problemas antes de que se convirtieran en críticos. El cliente agradeció nuestro enfoque proactivo, que contribuyó a generar confianza a largo plazo en nuestros servicios.

Un proveedor ideal ofrece servicios integrales, desde el diseño y la creación de prototipos hasta la producción en serie. Instalaciones como líneas de extrusión propias garantizan escalabilidad y flexibilidad. La experiencia en proyectos complejos y personalizados y una comunicación eficaz son cruciales para completarlos a tiempo y con éxito. Proveedores como XD TÉRMICO también ayudan a hacer frente a los riesgos de aprovisionamiento mediante especificaciones técnicas claras, cadenas de suministro sólidas y un estricto control de calidad durante la fabricación.

Este estudio de caso pone de relieve la importancia de una contratación eficaz en aplicaciones pesadas, desde aclarar los requisitos iniciales hasta garantizar el control de calidad y la entrega puntual. Al identificar los riesgos en una fase temprana y abordarlos de forma proactiva, XD THERMAL se aseguró de que el proyecto se completara con éxito, mejorando la eficiencia operativa general del cliente.

Para los profesionales de la contratación que trabajan con equipos pesados, esta historia de éxito pone de relieve la importancia de una comunicación clara, la coordinación técnica y la gestión de riesgos a lo largo de todo el proceso de contratación.

De cara al futuro, XD THERMAL sigue colaborando con más empresas de la industria pesada, contribuyendo al crecimiento y al éxito de proyectos complejos de gestión térmica.

Los riesgos de aprovisionamiento incluyen especificaciones técnicas poco claras, interrupciones en la cadena de suministro, limitaciones en la fabricación, ajustes de costes debidos a cambios en el diseño y retrasos logísticos. Estos riesgos pueden afectar a la calidad del producto, aumentar los costes y retrasar los plazos del proyecto. Abordar estos riesgos de forma proactiva garantiza una ejecución más fluida del proyecto y unos resultados de mayor calidad.

XD THERMAL aplica exhaustivos procedimientos de garantía de calidad, incluidas pruebas de Verificación del Diseño (DV) y Verificación del Proceso (PV). Durante la fase de muestreo, realizamos inspecciones completas para garantizar que el producto cumple todas las especificaciones. En la fase de producción en serie, realizamos inspecciones por muestreo para mantener la eficiencia y garantizar al mismo tiempo unos estándares de alta calidad.

Con más de diez años de experiencia en comercio exterior, XD THERMAL se anticipa a las interrupciones de la cadena de suministro y a los retos logísticos. Organizamos con antelación la manipulación de materias primas, la gestión de moldes y la coordinación de la línea de producción de la fábrica.

XD THERMAL selecciona proveedores logísticos fiables y mantiene una comunicación en tiempo real durante todo el proceso de envío. Si el proveedor logístico preferido de un cliente no está disponible o se retrasa, nos coordinamos internamente para organizar opciones de envío alternativas.

Las pruebas de DV y PV son cruciales para validar el rendimiento y la fiabilidad de un producto en condiciones reales. La verificación del diseño garantiza que el producto cumple sus especificaciones de diseño, mientras que la verificación del proceso confirma que el proceso de fabricación produce sistemáticamente productos de alta calidad. Estas pruebas exhaustivas ayudan a mitigar los riesgos tanto en la fase de muestreo como en la de producción en serie.

He trabajado en la gestión térmica de baterías durante más de 5 años, ocupándome de muchos proyectos internacionales. Si tiene curiosidad sobre los productos o servicios de refrigeración líquida de baterías, ¡no dude en hacerme cualquier pregunta!