Der Vormarsch der Elektrofahrzeuge hat die rasante Entwicklung der Batterietechnologie vorangetrieben, und die Weiterentwicklung der Batteriepacktechnologie ist eine entscheidende Komponente dieser technologischen Revolution. Von den anfänglichen CTP- über CTB- und MTC- bis hin zur CTC-Phase zielt jede Innovationsstufe darauf ab, die Energiedichte zu erhöhen, die Kosten zu senken und die Gesamtleistung des Batteriesystems zu verbessern. Die kontinuierliche Innovation in der Akkutechnologie hat nicht nur zu einer qualitativen Verbesserung der Reichweite von Elektrofahrzeugen geführt, sondern auch die gesamte Branche vorangebracht.

CTP (Cell-To-Pack) ist eine Technologie, die die dreistufige Pack-Struktur aus Batteriezellen, Modulen und dem Gesamtpack reduziert oder eliminiert. Sie umgeht den Standardmodulschritt, indem sie die Batteriezellen direkt in das Pack integriert, wodurch die Zwischenstufe der Module entfällt und die Raumnutzung und Energiedichte des Batteriepacks effektiv verbessert wird.

Derzeit gibt es zwei technologische Hauptansätze: die vollständig modullose Methode und die Verwendung größerer Module anstelle kleinerer.

Die neue Kirin-Batterie von CATL basiert auf der CTP-Technologie der dritten Generation. Mit dieser Technologie wird das modulbasierte Layout vollständig eliminiert und das separate Design der Querträger des Akkupacks, der unteren Kühlplatten und der Wärmeisolationspads weggelassen.

Stattdessen werden sie in eine multifunktionale elastische Zwischenschicht integriert. Dank dieser Konstruktion bietet der Kirin-Akku Vorteile wie eine schnelle Temperaturregelung, verbesserte Sicherheit, Unterstützung der 4C-Hochspannungs-Schnellladetechnologie und eine längere Lebensdauer des Akkus.

Niedrigere Herstellungskosten

Relativ einfache Wartung

Einfache Anpassung an unterschiedliche Fahrzeugmodelle und Anwendungsszenarien

Verbesserte Volumennutzung

Erhöhte Energiedichte

Erhöhte Schwierigkeiten bei der Bewältigung des thermischen Durchgehens

Hohe Prozessanforderungen

Schwierigkeiten bei Wartung und Ersatz

Lange Montagezeit des Akkupacks

Herausforderungen bei der Wiederverwendung von Zellen

Bei der CTB-Technologie entfallen die Konstruktion der Module und das Gehäuse des Batteriepacks. Dadurch können mehr Batteriezellen auf begrenztem Raum geladen werden, was die Batteriekapazität erhöht und Elektrofahrzeugen eine größere Reichweite ermöglicht.

Außerdem kann die CTB-Technologie das Gewicht der Fahrzeugbatteriekomponenten verringern und gleichzeitig die Gesamtfestigkeit des Fahrzeugs erhöhen. Darüber hinaus werden bei dieser Technologie die Blade-Zellen mit den Trays und den oberen Abdeckungen verbunden, so dass eine "Sandwich"-Struktur entsteht, die einer wabenförmigen Aluminiumplatte ähnelt, wodurch die strukturelle Gesamtfestigkeit des Batteriepakets verbessert wird.

Die CTB-Technologie ist das neueste integrierte Batteriezellenkonzept von BYD. Bei dieser Technologie wird die Bodenplatte des Fahrzeugs mit dem oberen Gehäuse des Batteriepakets kombiniert, wodurch eine einheitliche Oberfläche mit der Batterieabdeckung, den Schwellen sowie den vorderen und hinteren Querträgern entsteht. Die Abdichtung der Fahrgastzelle erfolgt durch Klebedichtungen, während der Boden über Befestigungspunkte an der Karosserie befestigt ist.

Erhöhte Batteriekapazität

Höhere Raumnutzungseffizienz

Erweiterte Reichweite

Hohe Sicherheitsleistung

Verbesserte Produktionseffizienz

Hohe Anforderungen an die Strukturfestigkeit der Batteriezellen

Erhöhte Gesamtkomplexität

Geringere Universalität

Anstieg der Produktions- und Wartungskosten

Die MTC-Technologie verfolgt den Ansatz, die Batteriemodule direkt in das Fahrzeugchassis zu integrieren. Durch die Kombination der Rahmenstruktur des Batterieträgers mit der Trägerstruktur der Fahrzeugkarosserie entsteht eine Doppelrahmen-Rundträgerstruktur. Die Innovation dieser Technologie liegt darin, dass gleichzeitig strukturelle Effizienz und Leichtbau erreicht werden, während die Abdichtung der Batterie durch die Träger der Fahrzeugkarosserie erfolgt.

Die von Leapmotor verwendete MTC-Technologie macht die traditionelle Batterieabdeckung überflüssig und integriert die Batteriemodule unter dem Fahrzeugboden. Die Batterie selbst besteht aus großen Modulen mit quadratischen Zellen, die in Reihe und parallel geschaltet sind. Das Modell, die Größe und die Parameter des Moduls bleiben mit dem vorherigen Design konsistent, was zu minimalen Änderungen an der Gesamtstruktur der Batterie führt, mit Ausnahme des Fehlens einer oberen Abdeckung.

Außerdem enthält die MTC-Technologie von Leapmotor eine zusätzliche Schicht aus wärmeisolierendem und feuerfestem Material zwischen dem Chassis und den Batteriezellen. Dies begrenzt nicht nur die schnelle Wärmeübertragung auf die Stahlteile, sondern isoliert auch die Batterie im Winter.

Leichte Konstruktion

Verbesserte strukturelle Effizienz

Erhöhte Reichweite

Hohe Sicherheitsleistung

Umweltfreundlichkeit

Effizienz der Integration muss verbessert werden

Höhere Kosten

Größere Gefahr des thermischen Durchgehens der Batterie

Komplexe Herstellungsverfahren und -technologien

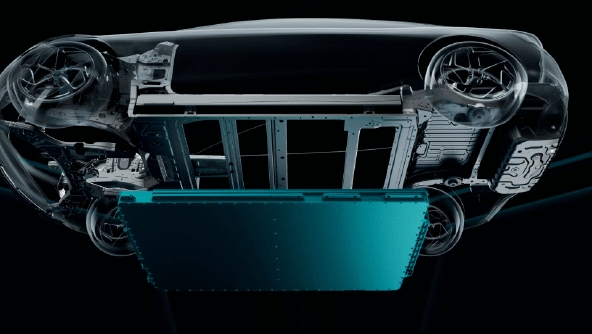

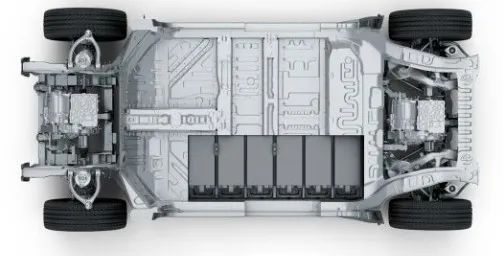

Bei der CTC-Technologie werden die Batteriezellen direkt in den Bodenrahmen integriert, wobei die oberen und unteren Platten des Bodens als Träger dienen. Batteriegehäuse. Sie stellt eine weitere Integration der CTP-Technologie dar, bei der die oberen und unteren Bodenplatten anstelle eines speziellen Batteriegehäuses und -deckels vollständig genutzt werden. Diese Konstruktion ist in den Fahrzeugboden und das Fahrgestell integriert, wodurch sich die Installationsform der Batterie grundlegend ändert.

Das Ziel der CTC-Technologie ist eine hochintegrierte und modulare Technologie, die darauf abzielt, die Montageprozesse zu vereinfachen und die Kosten zu senken, wobei der Schwerpunkt auf einem integrierten Designansatz liegt.

Tesla stellte auf dem Battery Day die 4680-Batteriezelle, die CTC-Technologie und die integrierte Druckgusstechnologie vor und kündigte an, dass das Berliner Werk die CTC-Technologie für die Produktion des Model Y einsetzen wird.

Der Ansatz von Tesla besteht darin, die Batteriezellen direkt auf dem Chassis anzuordnen, wodurch der Kabinenboden entfällt. Die Sitze sind direkt auf der Abdeckung des Batteriepacks montiert. Die Batteriestruktur ist in die gesamte Fahrzeugkarosserie integriert, wodurch ein hohes Maß an Integration erreicht wird und die Anforderungen an die Geschlossenheit des Batteriesystems erfüllt werden.

Zusätzlich, die Methode der Seitenkühlung und die mit Klebstoff gefüllte Struktur der Tesla-Batteriezellen tragen in gewissem Maße zur Begrenzung der Wärmeübertragung bei.

Verbesserte Raumnutzungseffizienz (höhere Reichweite und mehr Platz im Innenraum)

Bildung einer CTC-Doppelrahmen-Rundträgerstruktur (verbessertes Fahrgefühl und NVH)

Vereinfachte Struktur des Akkupacks

Geringerer Druck beim Komponentenmanagement

Rationalisierte Installations- und Fertigungsprozesse

Wirksamer Schutz der physikalischen Kollisionssicherheit für das Akkupaket

Mittel- bis langfristige Warnungen für den Zustand und die Lebensdauer von Batterien

Nicht austauschbare Batterie

Höhere Wartungskosten

Fragen der Sicherheit und der Wärmeableitung in Verbindung mit hohen Integrationsgraden