IGBT (Insulated Gate Bipolar Transistor) ist ein Halbleiterbauelement, das für die Ausgangssteuerung von Wechselstrommotoren in Elektrofahrzeugen, Eisenbahnlokomotiven und Elektrotriebwagen (EMU) verwendet wird. Herkömmliche Bipolar-Junction-Transistoren (BJT) haben zwar einen niedrigen Durchlasswiderstand, benötigen aber einen hohen Treiberstrom. Im Gegensatz dazu haben Metall-Oxid-Halbleiter-Feldeffekttransistoren (MOSFET) einen hohen Durchlasswiderstand, aber den Vorteil eines geringen Treiberstroms.

Der IGBT vereint die Vorteile beider Bauelemente: Er hat nicht nur einen geringen Treiberstrom, sondern auch einen niedrigen Durchlasswiderstand.

Das Funktionsprinzip des IGBT besteht darin, dass durch Anlegen einer positiven Gatespannung ein leitender Kanal gebildet wird, der den Stromfluss ermöglicht und den Schaltbetrieb erlaubt. Darüber hinaus wird durch die Einstellung der Gate-Spannung der Strom gesteuert, wodurch er für Anwendungen in der Leistungselektronik effizient steuerbar ist.

Er verfügt über eine höhere Spannungs- und Strombelastbarkeit sowie eine extrem hohe Eingangsimpedanz.

Er kann sehr hohe Ströme mit sehr niedrigen Spannungen schalten.

● Es handelt sich um ein spannungsgesteuertes Gerät, was zu keinem Eingangsstrom und geringen Eingangsverlusten führt.

● Die Gate-Ansteuerungsschaltung ist einfach und kostengünstig, was die Anforderungen an die Gate-Ansteuerung reduziert.

● Es kann durch Anlegen einer Spannung leicht ein- und ausgeschaltet werden.

Er hat einen sehr niedrigen Durchlasswiderstand und weist eine hohe Stromdichte auf (bei kleinerer Chipgröße).

● Er bietet einen höheren Leistungsgewinn im Vergleich zu BJT und MOSFET (höhere Schaltgeschwindigkeit als BJT).

● Seine bipolare Beschaffenheit verbessert die Leitfähigkeit.

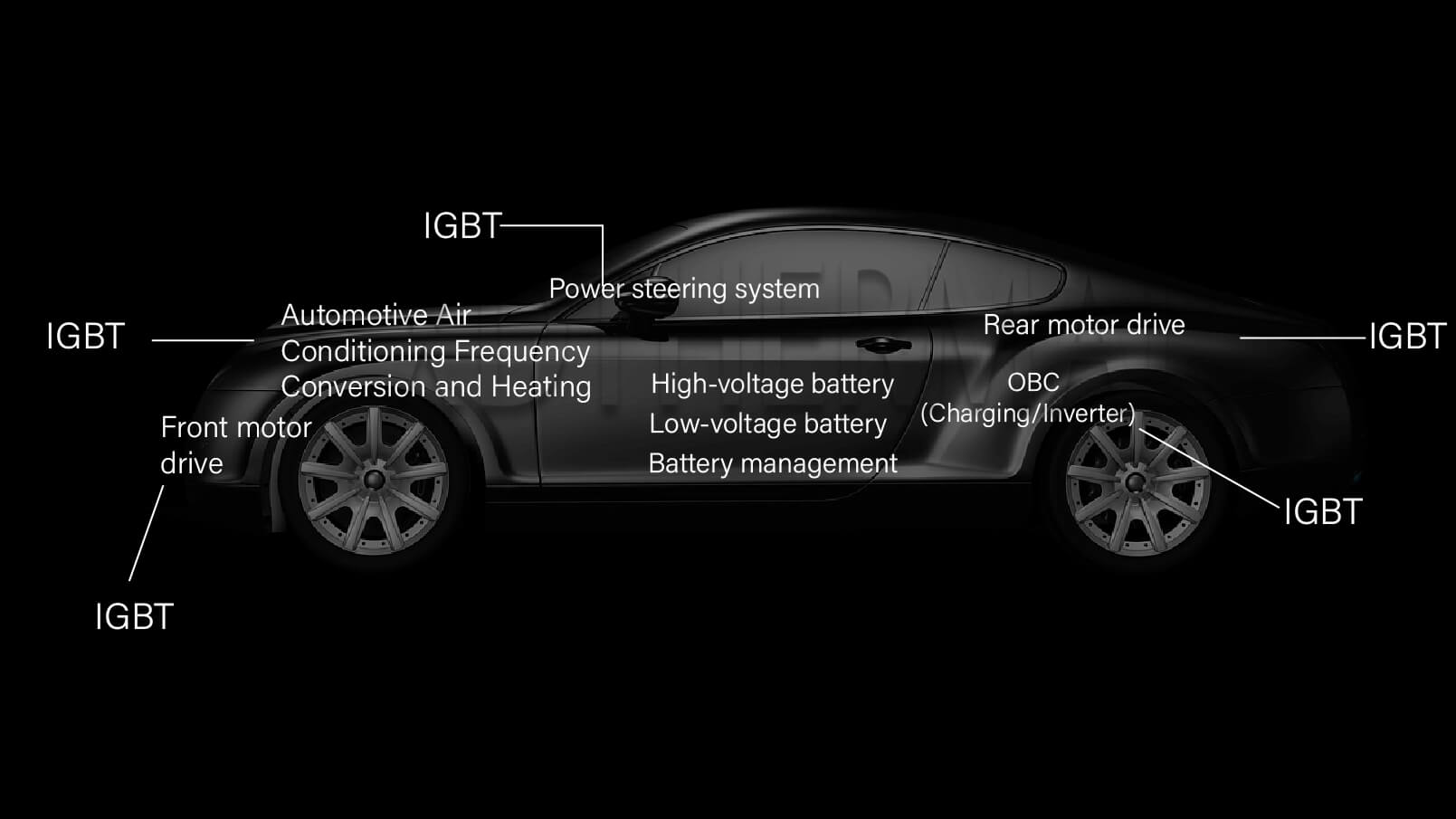

IGBT haben ein breites Anwendungsspektrum und werden in der Regel in leistungselektronischen Systemen eingesetzt, z. B. in Wechselrichtern, Motorantrieben, Stromversorgungen und Frequenzumrichtern. In Elektrofahrzeugen wird er in großem Umfang für Motorantriebe und Batteriemanagementsysteme eingesetzt. Seine hohe Leistungsdichte und Regelbarkeit ermöglichen eine effiziente Energieumwandlung und ein intelligentes Energiemanagement in Elektrofahrzeugen, was den Fortschritt in der Elektrofahrzeugtechnologie vorantreibt. Darüber hinaus spielen IGBTs eine entscheidende Rolle in verschiedenen Bereichen wie Transport, erneuerbare Energiesysteme und industrielle Automatisierung.

Der IGBT spielt eine entscheidende Rolle in Elektrofahrzeugen und den dazugehörigen Geräten und dient als zentrale technologische Komponente. Auf IGBT entfallen fast 10% der Kosten in Elektrofahrzeugen und etwa 20% in Ladestationen. Im Bereich der Elektrofahrzeuge werden sie hauptsächlich in den folgenden Bereichen eingesetzt:

Motorantrieb: Der IGBT spielt eine wichtige Rolle in elektrischen Steuerungssystemen und trägt durch die genaue Steuerung seines Einschaltzustands zur präzisen Motoreinstellung bei. Dadurch wird die Leistung und Energieeffizienz des Fahrzeugs verbessert. Die hohe Leistungsdichte und Steuerbarkeit des IGBT machen ihn zur idealen Wahl für die Motorsteuerung und ermöglichen ein effizienteres und flexibleres Fahrerlebnis.

Batterie-Management-System: Der IGBT ist ein wichtiger Akteur in Batteriemanagementsystemen. Batterien dienen als Energiespeicher in Elektrofahrzeugen, und die Steuerbarkeit und die hohe Eingangsimpedanz des IGBT machen ihn zu einem idealen Regler für Lade- und Entladevorgänge von Batterien. Durch die präzise Steuerung der IGBT-Schaltvorgänge werden schnelles Laden, effizientes Entladen, Strombegrenzung, Temperaturschutz und Überwachung des Batteriestatus erreicht, wodurch die Sicherheit gewährleistet, die Lebensdauer der Batterie verlängert und die Sicherheitsleistung verbessert wird.

Hilfssysteme: In Hilfssystemen steuert der IGBT Batteriekühlsysteme, regenerative Bremssysteme und Hilfsstromsysteme, um die Effizienz und Zuverlässigkeit des Fahrzeugsystems zu verbessern. In Batteriekühlsystemen wird der IGBT hauptsächlich zur Echtzeitüberwachung und -steuerung der Batterietemperatur eingesetzt. Durch den Erhalt von Temperaturinformationen über Sensoren kann der IGBT den Betrieb des Kühlsystems bei Bedarf anpassen.

Bremssystem: Beim Bremsen wird die durch die Radbewegung erzeugte mechanische Energie in elektrische Energie umgewandelt. Durch IGBT-gesteuerte Wechselrichtervorgänge wird diese elektrische Energie an Energiespeicher, in der Regel Batterien, übertragen. Bei diesem Prozess wird die beim Bremsen erzeugte Energie gespeichert, um eine Verschwendung zu verhindern. Anschließend kann diese gespeicherte Energie genutzt werden, um zusätzliche Leistung bereitzustellen und die Reichweite des Elektrofahrzeugs zu erhöhen.

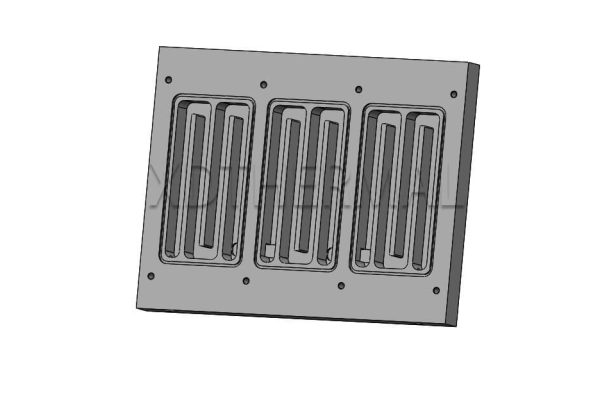

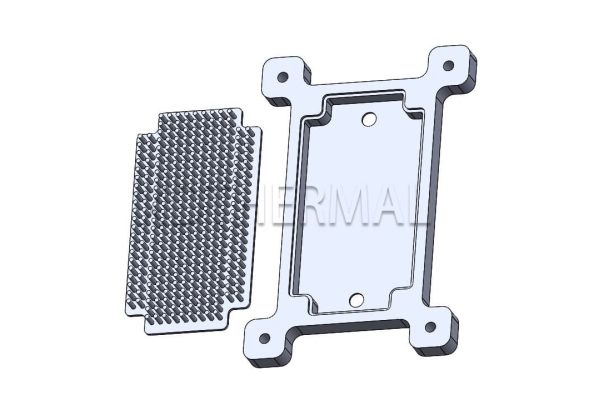

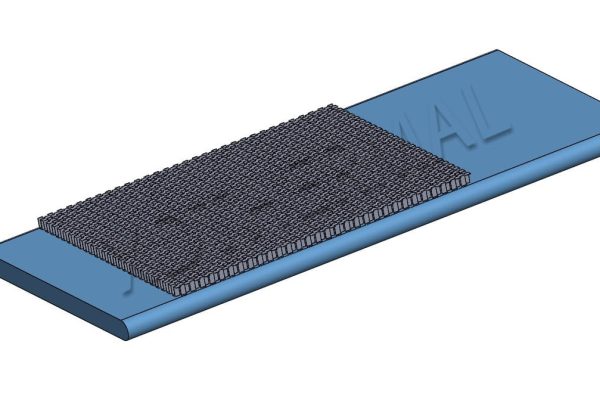

Die IGBT-Flüssigkeitskühlplatte ist ein wichtiges Bauteil zur Wärmeableitung, insbesondere zur Bewältigung der in elektronischen Hochleistungsgeräten erzeugten Wärme, wobei der IGBT häufig als primäres Leistungshalbleiter-Bauelement dient Diese Flüssigkeitskühlplatte besteht normalerweise aus einem Metallsubstrat, Kühlrohren und einem Kühlmedium. Das Funktionsprinzip besteht darin, dass das Kühlmedium in den Kühlrohren zirkuliert und die vom IGBT erzeugte Wärme aufnimmt und abführt. Die Flüssigkeitskühlplatte sorgt für eine wirksame Wärmeableitung und stellt sicher, dass der IGBT unter hohen Lastbedingungen eine angemessene Betriebstemperatur beibehalten kann, wodurch die Systemtemperaturen gesenkt, die Lebensdauer des Geräts verlängert und die Leistung der Leistungsmodule verbessert wird.

Deshalb, IGBT-Flüssigkeitskühlplatten sind für viele eine ideale Wahl geworden. In Bereichen wie Elektrofahrzeugen, Industrieautomation und Energieumwandlung fördert der weit verbreitete Einsatz von IGBT-Flüssigkühlplatten die effiziente Energienutzung und trägt zu den Zielen der nachhaltigen Entwicklung bei. Mit kontinuierlicher technologischer Innovation werden IGBT-Flüssigkeitskühlplatten auch in Zukunft eine entscheidende Rolle im Bereich der Wärmeableitung elektronischer Geräte spielen und den Fortschritt in der Leistungselektronik vorantreiben.