Welche Oberflächenbehandlungsmethode ist die beste für EV-Batteriekühlplatten?

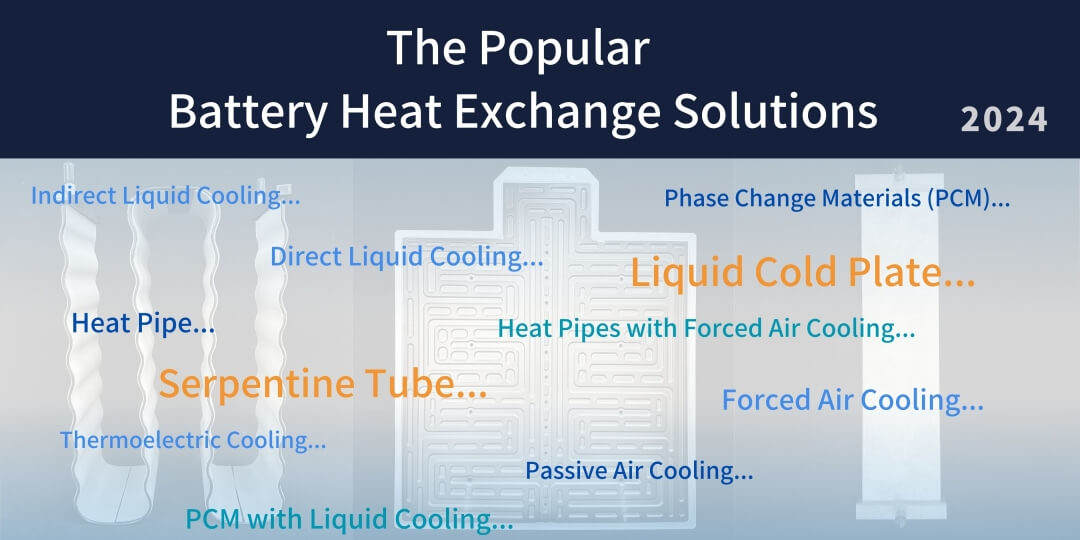

Which Surface Treatment Method is Best for EV Battery Cooling Plates? Are you frustrated by liquid cooling plates that corrode quickly, reduce efficiency over time, or fail under harsh conditions? Do you worry that untreated plates might lead to unexpected equipment breakdowns, compromised safety, or an unprofessional appearance that impacts your brand’s reputation? These challenges are common among companies that rely on untreated cooling plates, risking both performance reliability and long-term cost efficiency in critical applications. Surface treatment on liquid cooling plates prevents corrosion, enhances heat transfer, improves durability, ensures electrical safety, delivers a professional finish, and enables consistent performance in challenging environments. The ideal surface treatment—anodising, electroplating, specialized coatings, epoxy spraying, or UV coating—depends on your specific needs. By aligning the method with performance, cost, and durability goals, you can improve cooling efficiency, extend battery life, and ensure compliance with automotive-grade standards like IATF 16949 or better. Let’s dive deeper into each method, supported by data, industry standards, and real-world success stories and hopefully inspire your choices Table of Contents Why is surface treatment essential? As mentioned earlier, effective surface treatment maximizes heat transfer, protects against corrosion, and improves overall battery pack longevity, directly influencing EV reliability and operational costs. Studies indicate that well-treated cooling plates can enhance thermal efficiency by up to 20%, prolonging battery life and reducing maintenance. This ensures consistent performance even under extreme temperatures, humidity, and load cycles. According to a 2022 report in a leading automotive engineering journal, proper surface treatments can cut failure rates by 15-25% over a battery’s operational lifespan. As EV manufacturers face rigorous safety and performance regulations—such as UNECE R100 or IEC 62660—investing in the right surface treatment ensures robust, reliable performance and reduced downtime. What are the common surface treatment methods? From traditional approaches to cutting-edge finishes, multiple treatment…