Looking for Cost Reductions in Your Project?

Choose your plan👇👇

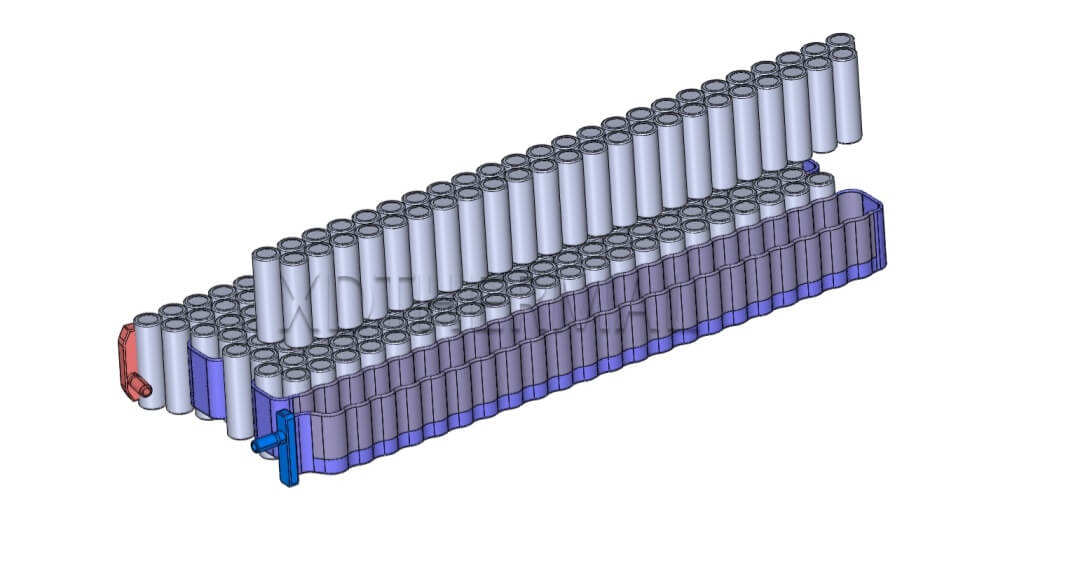

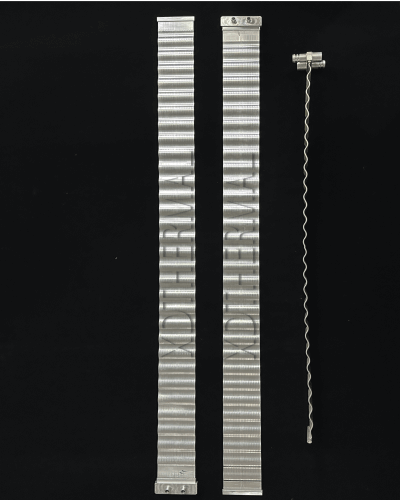

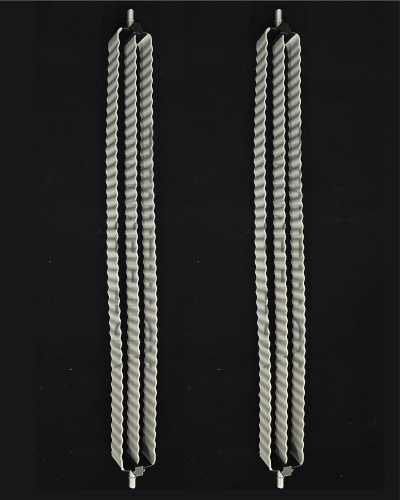

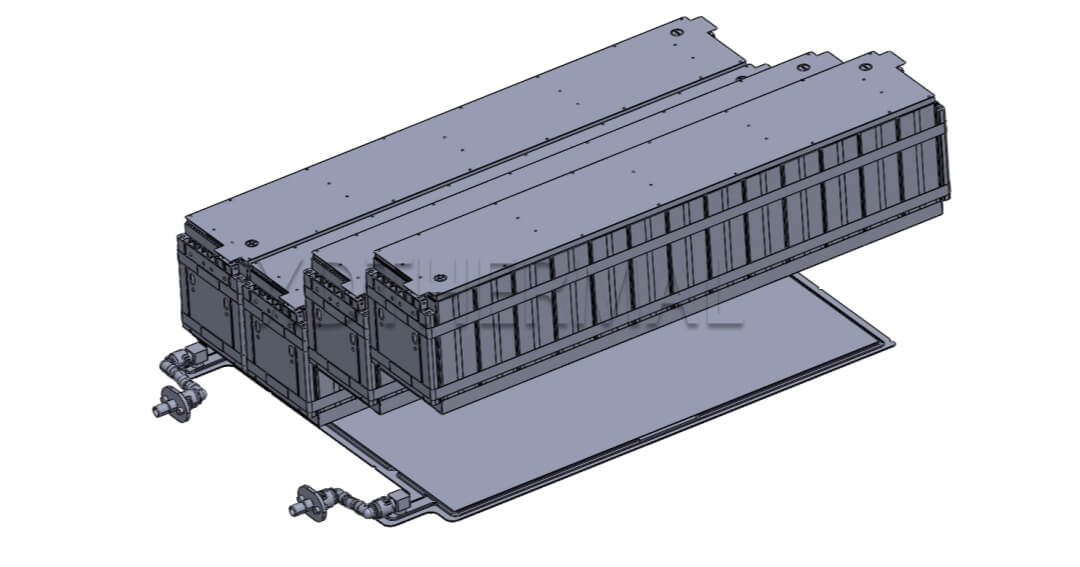

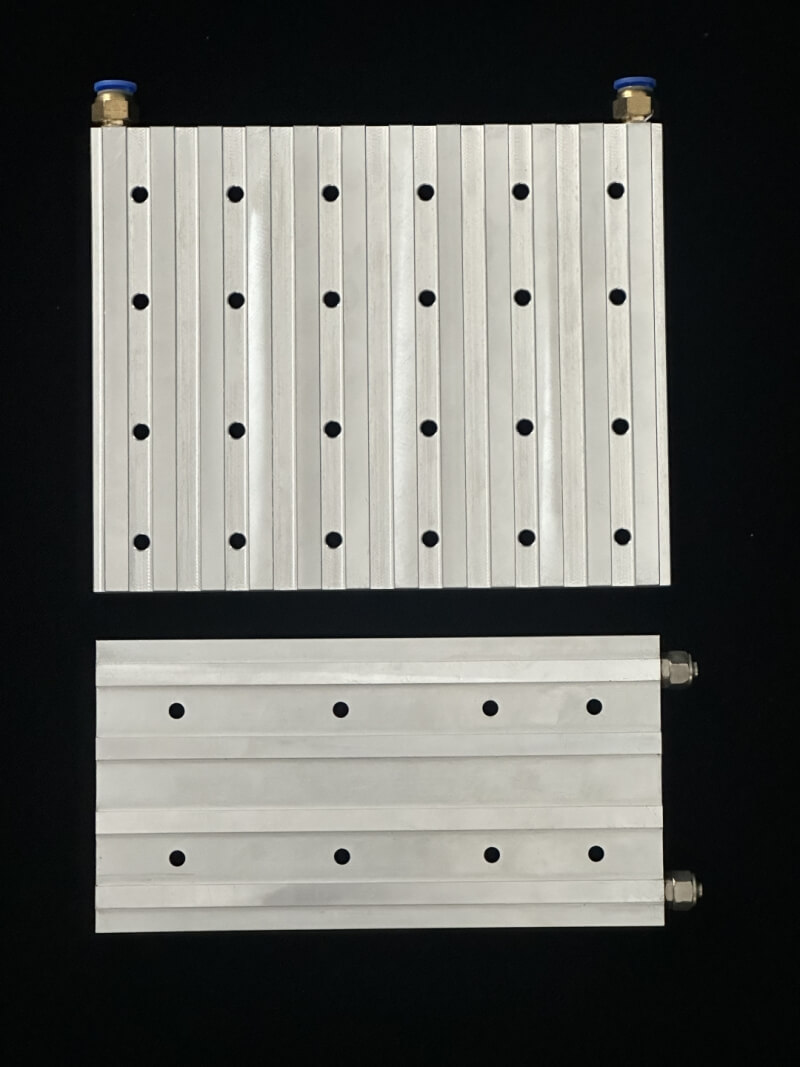

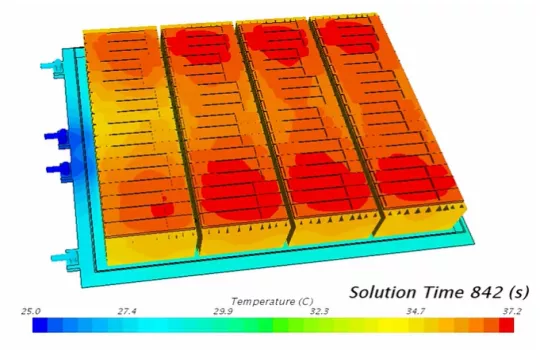

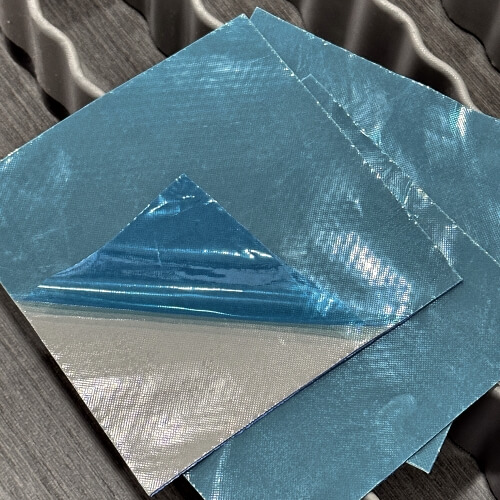

Material Selection

+

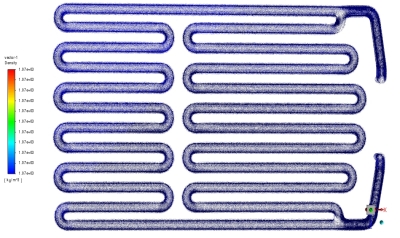

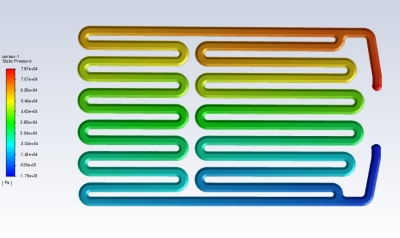

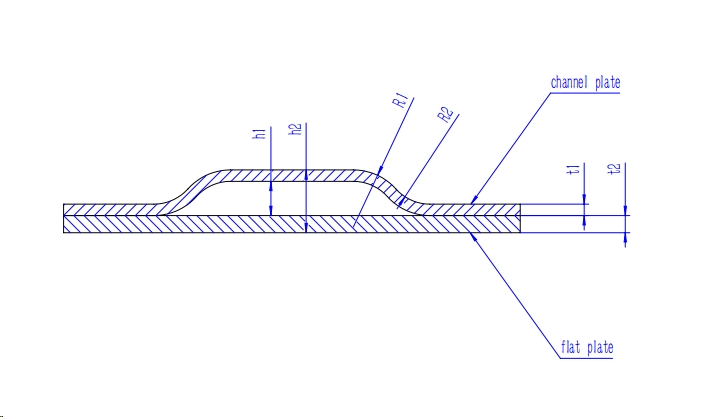

CAD Drawing Optimization

Reduce Procurement Costs by

15

6%

per projects