고객 리뷰

사람들이 뭐라고 하나요?

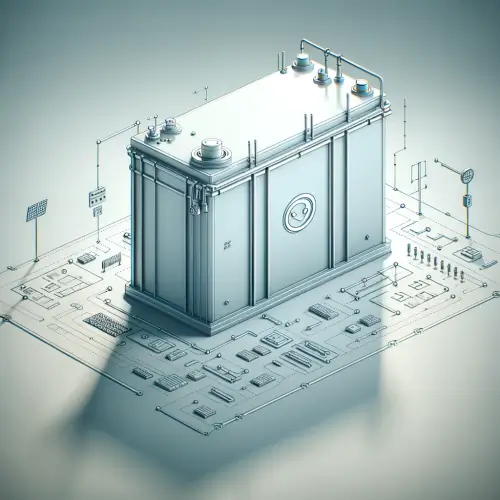

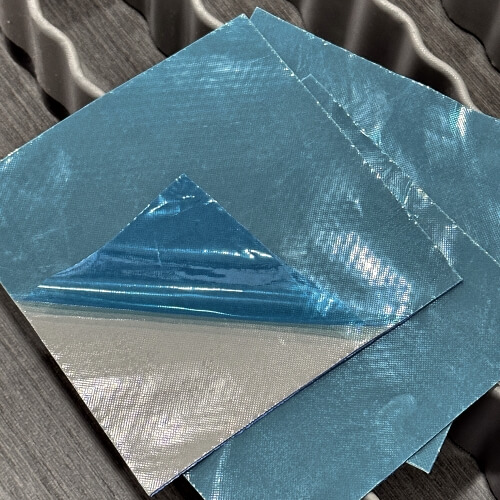

XD THERMAL와의 협업은 일반적인 공급업체 관계라기보다는 파트너십에 가깝게 느껴집니다. 그들은 시간을 들여 우리의 구체적인 요구 사항을 이해하고 최상의 솔루션을 찾기 위해 우리와 함께 노력합니다. 이러한 협업 정신은 여러 성공적인 프로젝트와 혁신으로 이어졌습니다.

로한 파텔

배터리 엔지니어

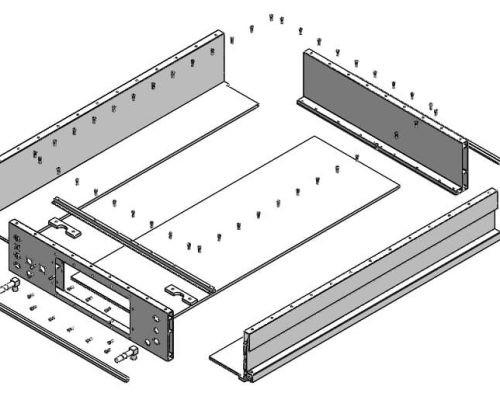

우리 업계에서는 안전이 가장 중요한데, 처음부터 빠르고 고품질의 교정 제품을 받을 수 있어 정말 안심이 됩니다. XD THERMAL와 함께 앞으로의 발전이 매우 낙관적입니다.

존 앤더슨

조달 관리자