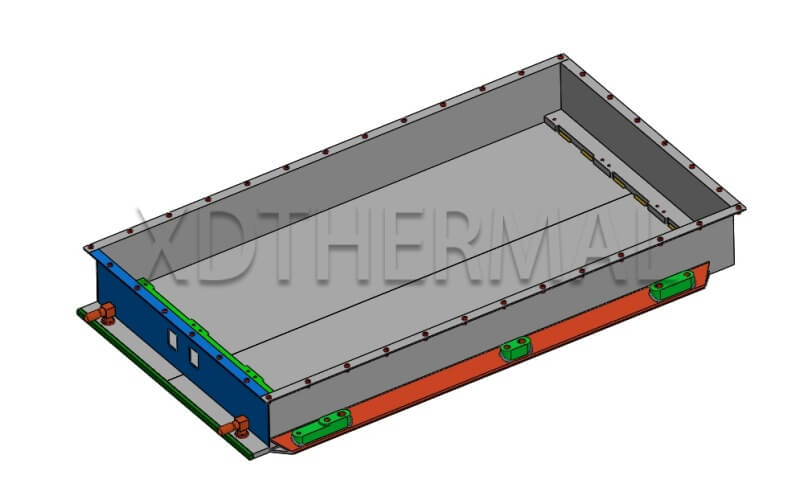

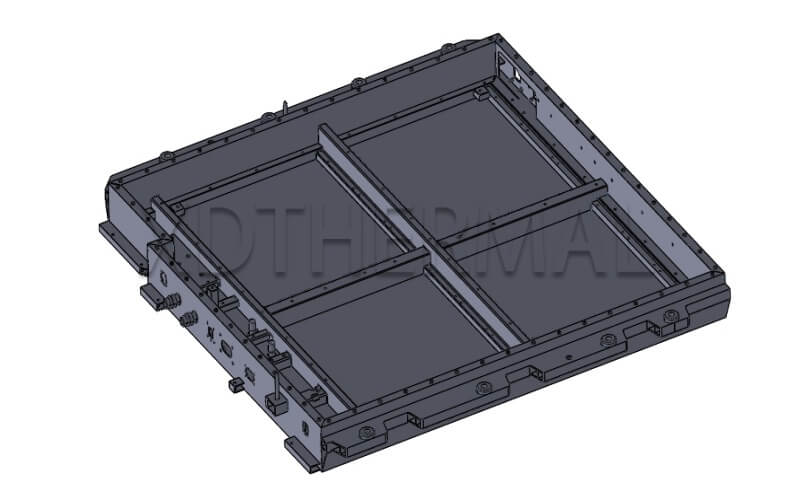

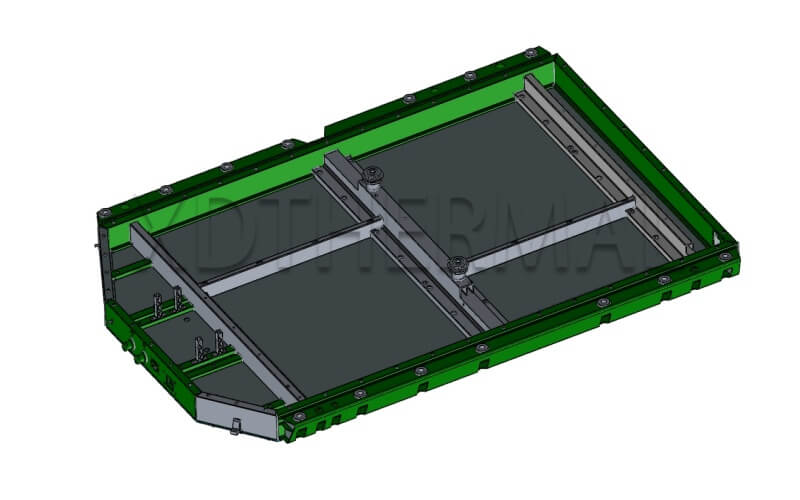

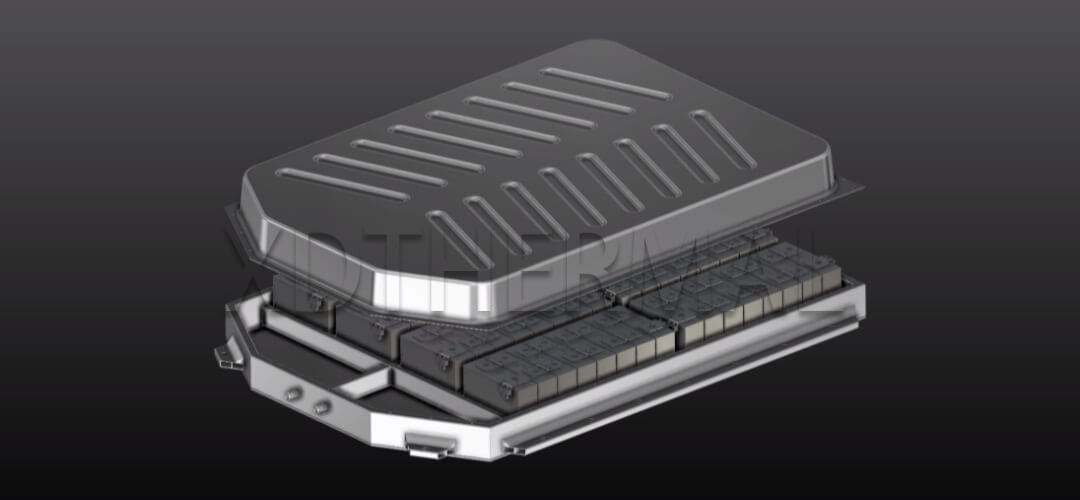

Custom Integrated Battery Pack Enclosure Manufacturer

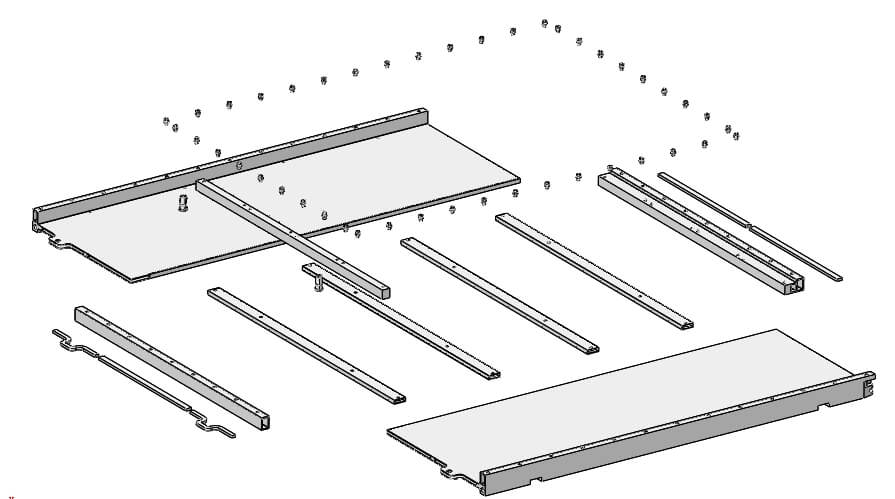

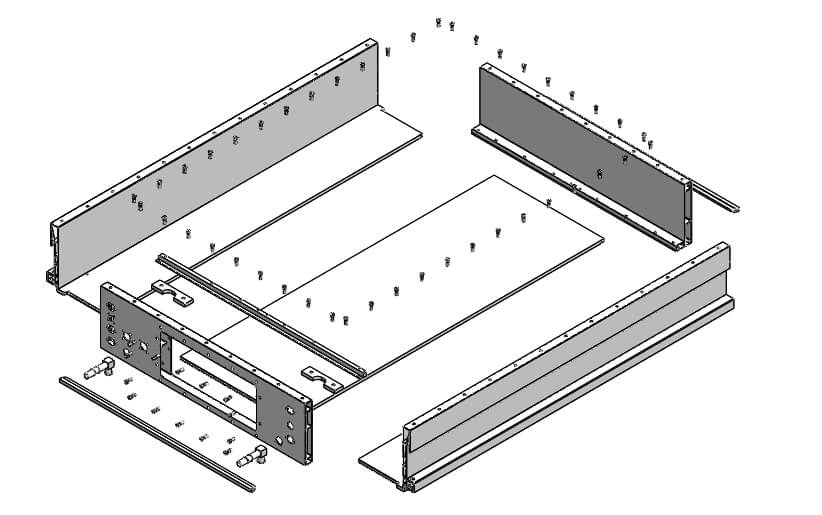

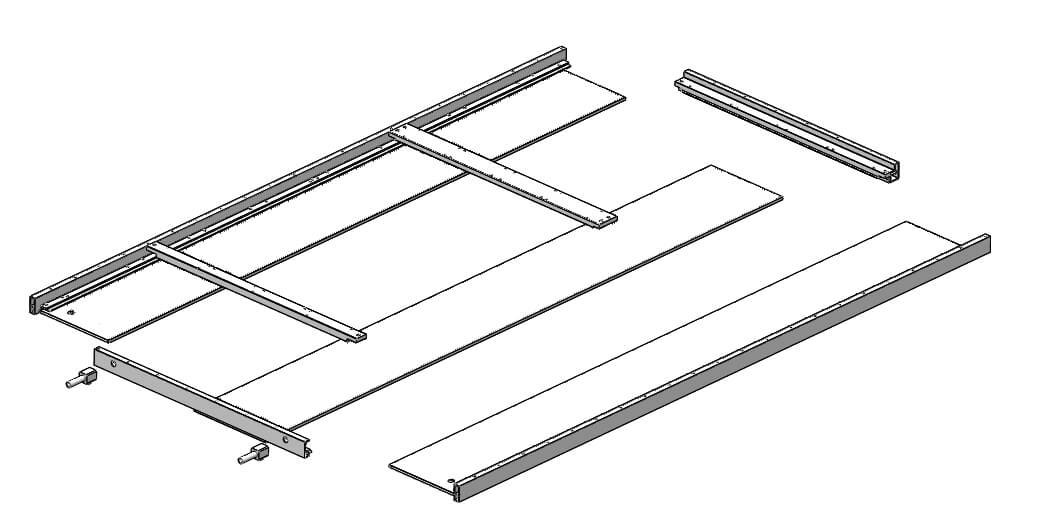

XD Thermal liquid cooling battery pack tray use automotive standard technology, deliver excellence and performance in battery heat dissipations for EV, ESS & heavy-duty. Fast design. Reliable supply. Built to spec.